The most spiritual fabric -Lotus fabric

The

lotus flower is adored for its characteristic of rising above the muddy water,

indicating how one can rise above defilements of life. Apart from motivation

for life, the plant also provides fibres which are used for making a rare kind

of cloth matching with the flawless virtues of the silk. Fibres extracted from

the lotus flowers of the Myanmar , Cambodia lakes are spun by hand and woven within 24

hours making a fabric similar to silk.

Extracting

fibres from lotus stems have been in practice since long. Later during the 90's

designers of Japan setup workshops to create a foreign market for their fabric.

But due to low demand in Japan, lotus fibre fabric remained a rare and handmade

textile.

Lotus

plant is believed to have healing abilities and wearing a fabric made from

lotus fibres is also believed to have the same effects. Lotus plants are pure

by virtue, and they radiate this purity through their fibres. By wearing lotus

fibre fabrics, one feels calm, peaceful and meditative. It also cures the

wearer from headaches, heart ailments, asthma, and lung issues. The fabrics are

100 percent organic, and hence are environmentally friendly.

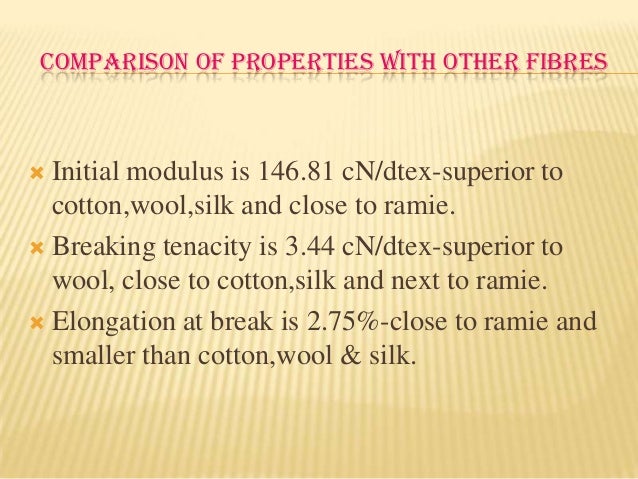

In order to understand the structure and properties of lotus fibers to provide theoretical basis for developing lotus fiber fabric, the research on chemical components, morphological structure, aggregation structure and mechanical properties of nature lotus fiber is implemented by chemical quantitative analysis, scanning electron microscope, infrared spectra, X-ray diffraction analysis and so on. The result is shown. First, lotus fiber is consist of cellulose, hemicellulose, fat waxy, lignin, ash, pectin, hydrotrope, amino acids and so on, where cellulose is the main ingredient. The lotus fiber, showing ribbon spiral revolving structure vertically, has clearly imperceptible cross striation, and is bundle fiber composed of many monofils. Then, the cross-sectional of lotus monofil is circular or similar to circular. Lotus fiber is typical cellulose structure with 48% crystallinity and 60% orientation. The density, fineness and moisture regain of lotus fiber is respectively 1.1848 g/cm 1.55 dtex, 12.32%. Lotus fiber is high strength and low stretch fiber with initial modulus 146.81 cN/dtex, breaking strength 3.44 cN/dtex and breaking elongation 2.75%.

In order to understand the structure and properties of lotus fibers to provide theoretical basis for developing lotus fiber fabric, the research on chemical components, morphological structure, aggregation structure and mechanical properties of nature lotus fiber is implemented by chemical quantitative analysis, scanning electron microscope, infrared spectra, X-ray diffraction analysis and so on. The result is shown. First, lotus fiber is consist of cellulose, hemicellulose, fat waxy, lignin, ash, pectin, hydrotrope, amino acids and so on, where cellulose is the main ingredient. The lotus fiber, showing ribbon spiral revolving structure vertically, has clearly imperceptible cross striation, and is bundle fiber composed of many monofils. Then, the cross-sectional of lotus monofil is circular or similar to circular. Lotus fiber is typical cellulose structure with 48% crystallinity and 60% orientation. The density, fineness and moisture regain of lotus fiber is respectively 1.1848 g/cm 1.55 dtex, 12.32%. Lotus fiber is high strength and low stretch fiber with initial modulus 146.81 cN/dtex, breaking strength 3.44 cN/dtex and breaking elongation 2.75%.

Lotus fiber is a

natural cellulose fiber isolated from lotus petiole. Botanically, the

fiber is the thickened secondary wall in xylem tracheary elements. In

order to obtain essential information for the preparation and processing

of lotus fibers, the fine structure and properties of lotus fibers were

investigated by the aid of transmission electron microscopy (TEM),

confocal laser scanning microscopy (CLSM), atomic force microscopy

(AFM), X-ray diffraction (XRD), and so on. The results show that lotus

fibers display a rough surface topography and an internal structure

different from common plant fibers. The percent crystallinity and

preferred orientation of crystallites in lotus fibers are 48% and 84%,

respectively. Considering the average breaking tenacity and Young's

modulus, lotus fibers are similar to cotton. The elongation of lotus

fibers is only about 2.6% while their moisture regain is as high as

12.3%.

Manufacturing Process:

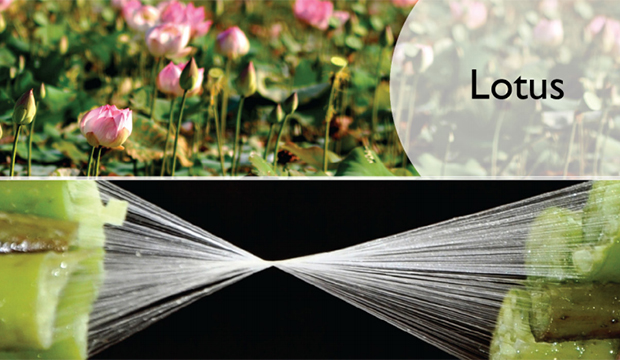

The entire process of fibre extraction, spinning

it into yarn and making the fabric is completely handmade making the process

time consuming. This also limits the quantity of the fabric produced. Stems of

the lotus plants are collected, cut, snapped, and twisted to expose its fibres.

These are thin and white filaments around 20 to 30 in number. These thin

filaments are rolled into a single thread. Around 20-25 women are needed to extract

fibres this way for one weaver to work with.

Fibres

extracted from the stem are spun into yarn. Extracted fibres are placed in the

skeins on a bamboo spinning frame preparing them for warping. Yarns are made

by placing the fibres on a bamboo spinning frame and transferring the thread

into winders for warping. With much care, not to get tangles, threads are made;

up to 40 meters long. The threads are then taken from the warping posts,

and are coiled into huge plastic bags. Yarns for the weft are wound into bamboo

bobbins.

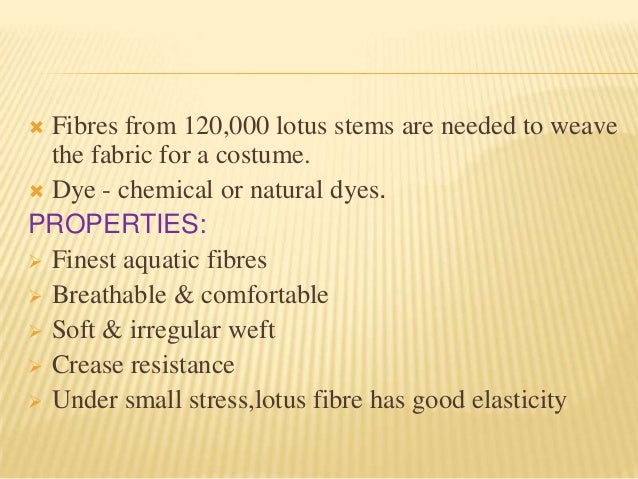

Fabrics

are woven in the traditional Cambodian loom. Excess warp is stored and later

released during the course of weaving. The woven fabric has a width of

approximately 24 inches. During the process of weaving, threads are frequently

moistened with water, as lotus fibres need to be kept cool. Around 1, 20,000

lotus stems are required to make fabrics adequate for making a costume. The

fibres are very delicate and should be woven within 24 hours of being extracted

so as to prevent its deterioration.

Lotus

fibre fabric gets the fashion branding:

The

fabric looks like a blend of linen and silk, and posse's wrinkle resistant and

breathable qualities given by the molecular makeup of the lotus plant. It has a

milky yellow hue. Textile baron Mr Pier Luigi Loro Piana, owner of the Italian

luxury brand Loro Piana, happened to see the fabric. Impressed by the fabrics

breathable, and wrinkle resistance capacities, Pina travelled to Myanmar where

he learnt more about the fabric. He offered by buy around 55 yards of fabric

for a month for his company. Jackets of Loro Piana made from lotus fibre

fabrics cost up to $ 5,600 and have a good market in countries like Japan and

Europe.

Lotus

fibres have age old tradition of making robes for Buddhist monks of highest

ranks, and to decorate Buddha idols. Traditional fabric weaving is difficult to

be translated into mass production. Involving exclusive craftsmanship, and

time consuming in its making, lotus fibre fabrics remain as a true luxury only

for the privileged ones.

The plain woven pure Lotus fabric is recommended for jackets and dresses, as it is hard wearing and soft.

The airy pure Lotus fabric is recommended for scraves, as it is especially breathable and light.

Lotus fabric has unique properties: it is naturally soft, light, especially breathable, and almost wrinkle free. It is also a very eco-friendly fabric containing no chemicals or toxic products. It’s probably the most ecological fabric

in the world. We transform a stem that would have turned to waste into a

quality textile, while not using any polluting energy during the

entirety of the production process.

Starting with this uniquely soft and breathable fabric, we developed the first prototypes of our new collection. Our lotus fabrics are all made possible thanks to the skill of our artisans who possess unparalleled expertise, and create strikingly precise and detailed designs.

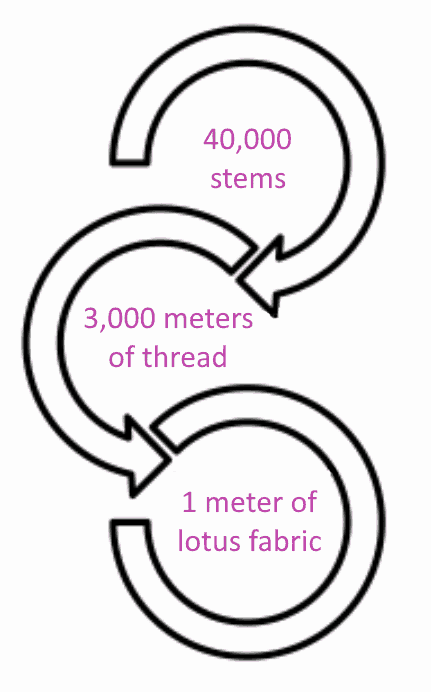

Some figures around lotus fabric manufacturing:- 4 harvests of lotus per day

- 1 hectare of lake per spinner

- 1 spinner can produce up to 250 meters of thread a day

- Around 30kg of stems are needed to produce 250 meters of thread

- 1 experimented weaver can weave 1 meter of lotus fabric a day

The most ecological fabric

- A waste (lotus stems) transformed into a quality textile

- No chemical or toxic product

- Hand spun and woven following traditional Cambodian methods

- No use of non-renewable energy

How to take care of Lotus fabric?

- Hand wash

- Do not bleach

- Dry flat in the shade

- Do not require iron

- Dry-clean: petroleum solvent only

Lotus Fabric Manufacturing Process

6 comments:

Good and nice experience.

darshith581@gmail.com

Useful information

I bought some lotus fiber roving. I’m wondering if it was processed. Like bamboo fiber

I am so happy that I have found your blogs on realistic fake flowers

. I regularly read your blogs and find them really good. Keep sharing!

I have found that this site is very informative, interesting and very well written. keep up the nice high quality writing. Nearest Fabric Store

This article is very helpful, I wondered about this amazing article.. This is very informative.

“you are doing a great job, and give us up to dated information”.

Thanks for sharing such unique content. Please keep it up.

Preserved Flower Wholesale

Post a Comment