ACRYLIC FIBRE

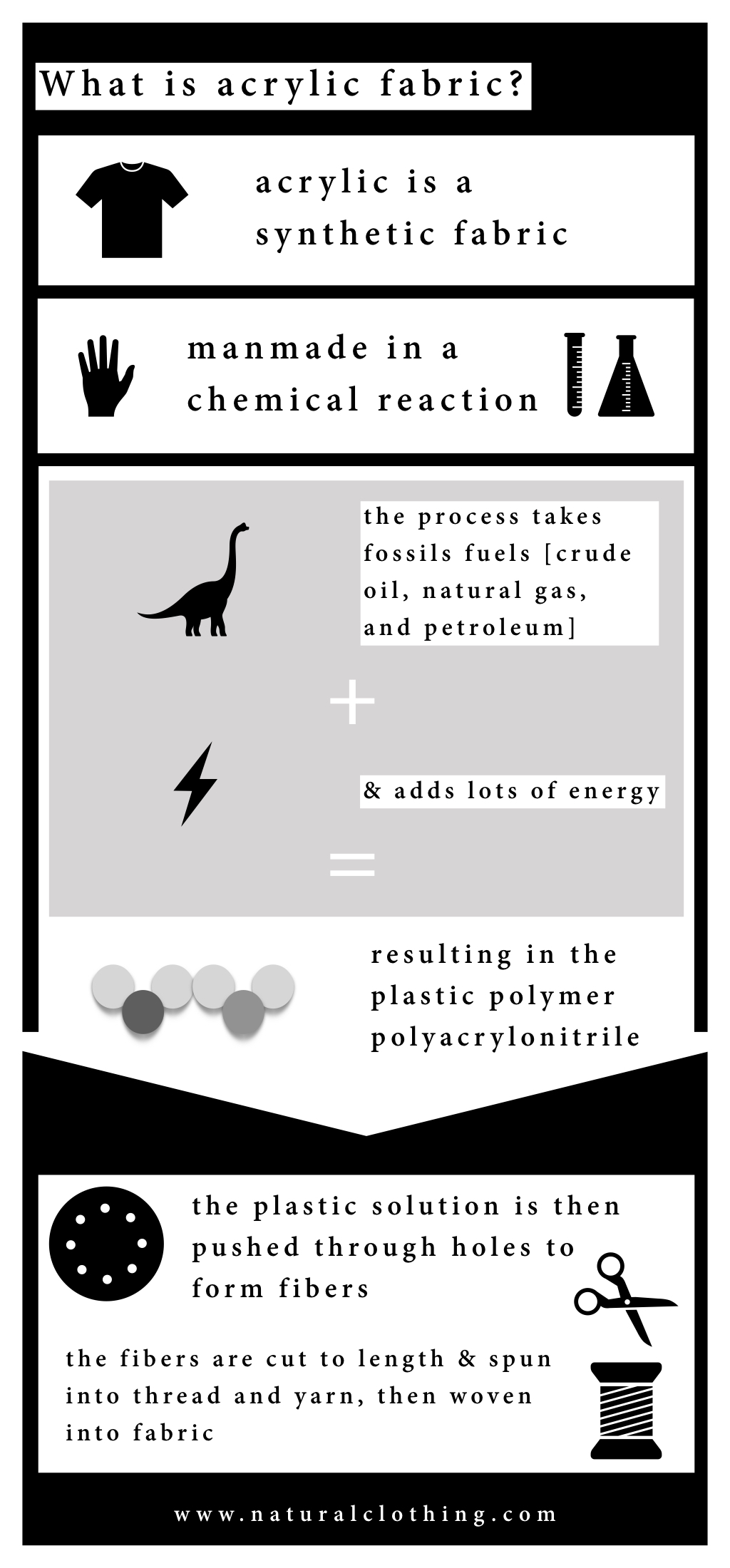

Acrylic fiber is a synthetic fiber that closely resembles wool in its character. According to the definition of the ISO (International Standards Organization) and BISFA (International Synthetic Fiber Standardization Office), fibers which contain a minimum of 85% acrylonitrile in their chemical structure are called "Acrylic Fibers".

History

Like many other synthetic textile fibers, the American DuPont Corporation originally developed acrylic fiber. This firm had already become famous around the world for the development of nylon and the mainstreaming of polyester production, and when acrylic fiber was invented in the 1940s, the world saw this development as simply the next step in DuPont’s rapid ascent to a dominant position in the world’s textile markets.

However, acrylic fiber didn’t become notably popular until the 1950s. It’s possible that the success of DuPont’s other synthetic textiles contributed to this slow mainstreaming of acrylic fiber; this company had already replaced silk with nylon and cotton with polyester, which may have reduced consumer receptivity to this company’s new wool replacement, acrylic.

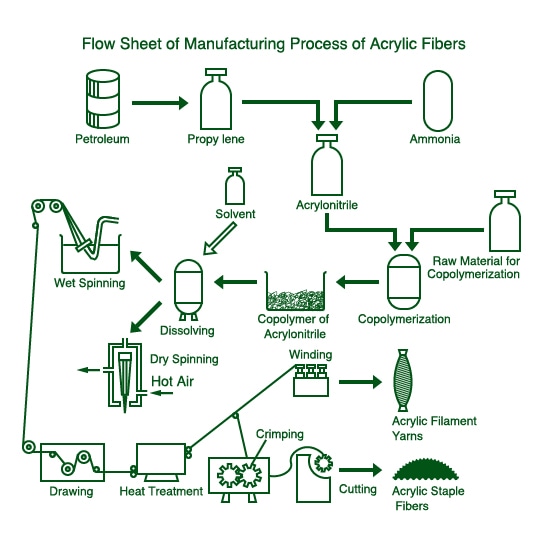

A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 85% by weight of acrylonitrile units [-CH2-CH(CN)-] (FTC definition). Acrylic fibers are produced by two basic methods of spinning (extrusion), dry and wet. In the dry spinning method, material to be spun is dissolved is a solvent. After extrusion through the spinneret, the solvent is evaporated, producing continuous filaments which later may be cut into staple, if desired. In wet spinning, the spinning solution is extruded into a liquid coagulating bath to form filaments, which are drawn, dried, and processed.

Acrylic fibres are synthetic fibers made from a polymer (polyacrylonitrile) with an average molecular weight of ~100,000, about 1900 monomer units. To be called acrylic in the U.S, the polymer must contain at least 85% acrylonitrile monomer. Typical comonomers are vinyl acetate or methyl acrylate. The Dupont Corporation created the first acrylic fibers in 1941 and trademarked them under the name "Orlon".

Raw Material

Acrilonitrile is the main main raw material for the manufacture of acrylic .

1st Method

2nd Method

Ethylene--Air Oxidation--> Ethylene oxide + HCN--> Ethylene cyanahydrin--Dehydration at 300 deg C (catalyst)--> Acrylonitrile

Production Process of Acrylic Fiber

The acrylic process is a "one step technology", with the following main characteristics:

- Polymerization in solution

- Direct feeding of the dope to spinning

- Wet spinning.

- DMF as solvent for both polymerization and spinning

|

| Fig: Production Process of Acrylic Fiber |

- Acrylic has a warm and dry hand like wool. Its density is 1.17 g/cc as compared to 1.32 g/cc of wool. It is about 30% bulkier than wool. It has about 20% greater insulating power than wool.

- Acrylic has a moisture regain of 1.5-2% at 65% RH and 70 deg F.

- It has a tenacity of 5 gpd in dry state and 4-8 gpd in wet state.

- Breaking elongation is 15% ( both states)

- It has a elastic recovery of 85% after 4% extension when the load is released immediately.

- It has a good thermal stability. When exposed to temperatures above 175 deg C for prolonged periods some discolouration takes place.

- Acrylic shrinks by about 1.5% when treated with boiling water for 30 min.

- It has a good resistance to mineral acids. The resistance to weak alkalies is fairly good, while hot strong alkalies rapidly attack acrylic.

- Moths, Mildew and insects do not attack Acrylic.

- It has an outstanding stability towards commonly bleaching agents.

- Superior in warm retention, light and warm.

- Excellent in color development and can be dyed in desired color.

- Little affected by sunlight.

- Thermoplastic

| |||||||||||||||||||||||||

| |||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||

Types of Acrylic Fibres

There are four main types of acrylic fabric:

- Acrylic

To be considered normal acrylic fabric, this type of fibre must contain at least 85% pure acrylonitrile. After texturizing, acrylic fibres have a light bulky wool-like hand and overall wool-like aesthetics. The fibres are resilient and possess an excellent acid resistance and sunlight resistance.

- Modacrylic

This acrylic fibre variant is composed partially of acrylonitrile, but a variety of other polymers are also used in its production. For instance, modacrylic contains a high degree of vinylidene chloride as such, fabrics made from modacrylic fibre generally have better drapability, wrinkle-resistance, more heat sensitive but more flame resistant and durability than normal acrylic fabrics.

Modacrylic may also resist pilling and abrasion better than acrylic fibre. Modacrylics possess warm wool-like aesthetics and a generally bright luster. Lastly, modacrylic fabrics may hold their shape better than normal acrylic fabrics.

- Nytril

Unlike acrylic fabric, which is mainly composed of acrylonitrile, nytril is primarily composed of vinylidene dinitrile. Nytril fibres are made up of polymers containing at least 85% vinylidene dinitrile units, which appear at least every other unit in the polymer chain. The comonomer used in Nytril synthesis is vinyl acetate.

While nytril hasn’t been made in the United States since the 1960s, it is still produced in the Asian markets. Since nytril is hard to dye, however, it never became highly popular, and it isn’t produced in large quantities anywhere in the world.

- Lastrile

Lastrile is an elastic form of acrylic that is made by mixing a type of chemical called a diene with acrylonitrile and a diene such as butadiene and contain 10%-50% acrylonitrile units. Lastrile fibres have not been commercially produced. This fabric is used in similar applications to acrylic in which greater elasticity is desired.

- Acid:It has good resistance to mineral acid.

- Alkali:The resistance to weak alkali is fairly good but hot strong alkali damages this fibre.

- Solvent:It has excellent resistance to common solvents, oils, greases, and natural salts.

- Water:moisture regain of this fibre varies from 1.5% to 3%. Easy to wash and quick drying.

Properties of Acrylic Fibre

Acrylic fibre closely resembles the look and feel of wool fibres and it has properties as follows:

- Acrylic has a warm and dry hand like wool. Its density is 1.17 g/cc as compared to 1.32 g/cc of wool. It is about 30% bulkier than wool. It has about 20% greater insulating power than wool.

- Acrylic has a moisture regain of 1.5-2% at 65% RH and 70 deg F.

- It has a tenacity of 5 gpd in dry state and 4-8 gpd in wet state.

- Breaking elongation is 15% (both states)

- It has an elastic recovery of 85% after 4% extension when the load is released immediately.

- It has a good thermal stability. When exposed to temperatures above 175 deg C for prolonged periods some discolouration takes place.

- Acrylic shrinks by about 1.5% when treated with boiling water for 30 min.

- It has a good resistance to mineral acids. The resistance to weak alkalies is fairly good, while hot strong alkalies rapidly attack acrylic.

- Moths, Mildew and insects do not attack Acrylic.

- It has an outstanding stability towards commonly bleaching agents.

- Easy to wash and good dimensional stability.

- Resistance to damage by moths and chemical substances.

- Excellent color-fastness and dyeability in brilliant colors.

- Highly resistant to sunlight.

- Lightweight, soft, and warm, with a wool-like touch

- Like polyester and nylon, acrylic fabric is hydrophobic– meaning it repels water. This can lead to bacteria growth in the fabric which may compromise the structure and cause odor.

Dyeing Acrylic Fibres

The variable chemical units in the fibre allowed for fibres of differing dyeing behavior, and some were produced to be dyeable with acid dyes, as wool is.

In the early 2000s, most acrylic fibre variants are dyed with basic (cationic) dyes. Many early synthetic dyes (including Perkin’s Mauve were basic dyes, and these were adopted for acrylics, but dyemakers later developed “modified” basic dyes specifically for use with these fibres. Disperse dyes may also be useful for pale shades. A considerable amount of acrylic and modacrylic fibre is colored during manufacture, either as “solution dyed” fibre or by applying dye to the fibre immediately after spinning in “gel-dyeing.”

The short product life & long landfill life of acrylic fabric

On its own, acrylic fabric is not resistant to abrasion. Because of this, acrylic fibre is often blended with more resilient fibres to create a more durable product. Acrylic fabric is also highly likely to pill. Needless to say, the product lifespan of acrylic fabric clothing is not considerably long. Then it enters the landfill, where acrylic fabric can last up to 200 years and release toxic chemicals into the environment on its long journey to decomposition. Two hundred years. If you thought that picture of your grandma in the dress with puff sleeves was funny and outdated, just wait until your great-great-great-great-great grandkid finds your Forever21 DayGlo crop top. Because it might still be around! Very pilled, bacteria ridden, and possibly singed. Not to mention, leaching toxins. So if nothing else, wear biodegradable clothing to save face with your heirs.

The Impact on Environment

Since acrylic fabric is not biodegradable, its environmental impact is largely negative. Also, the production processes used to make acrylic fabric harm workers and the ecosystems surrounding manufacturing facilities.

The production processes used to make acrylic fabric are highly volatile, and production plants that manufacture this fibre are constantly at risk of exploding if necessary safeguards fail. A variety of toxic substances are used in the production of acrylic fabric, and if these substances aren’t handled or disposed of correctly, they enter surrounding ecosystems and harm wildlife and human inhabitants. The gases produced in acrylonitrile manufacturing are so harmful that legislation requires they be properly filtered in a closed environment before they can leave a production facility.

Unlike polyester and some other synthetic fabrics, it is practically impossible to recycle acrylic fabric, which means that there is no effective means of disposal of acrylic garments once they are produced. Acrylic fibre is not biodegradable, so it simply accumulates in the environment and will stay there for hundreds of years until it slowly starts to break down.

The tiny fibre fragments produced when consumers wash synthetic fabrics enter the water supply and poison ecosystems. This microfibre crisis is threatening to make water undrinkable in high-density urban areas in which high water consumption and inadequate drinking water filtration techniques result in high concentrations of fibres in the hydrosphere.

For instance, a British scientist recently found that a single load of washed clothes can create up to 700,000 microfibres, and these microfibres then end up on shorelines all over the world. These microfibres simply add to the pandemic crisis of plastics in the oceans.

Additionally, as a volatile organic compound (VOC), acrylonitrile has the potential to create ground ozone, which poisons plants and reduces crop yield. It’s unclear, however, how frequently acrylic fibre production causes this environmentally harmful effect.

Like most other synthetic fibres, acrylonitrile is a fossil fuel derivative. Therefore, production of acrylic fabric furthers human consumption of fossil fuels, and it also takes up fossil fuels that could have been used for vital energy production applications.

Health Risks

In addition to being hazardous to the environment, acrylic fabric may also be hazardous to your health.

Acrylic fibre is made from the polymer polyacrylonitrile. Polyacrylonitrile is a flammable, colorless liquid that is created from polypropylene. The EPA found that inhaling polyacrylonitrile gives the victim similar symptoms to cyanide poisoning. In fact, when exposed to polyacrylonitrile, our bodies metabolize the chemical into cyanide. This metabolization can take place after exposure to the chemical through skin contact, ingestion, or inhalation.

As early as 1979, the U.S. Environmental Protection Agency (EPA) became concerned that residual monomers in acrylic fabric may be carcinogenic. This suspicion has since been substantiated by the U.S. Centers for Disease Control and Prevention; every time your skin comes into contact with acrylic fibres, your chances of developing cancer increase.

On its own, acrylic fabric is highly flammable, which means it must be treated with toxic flame retardants to avoid the possibility of grievously injuring the wearer. The types of flame retardants used are called organophosphates, and these toxic compounds gradually accumulate in the body.

Exposure to synthetic fibres in general during the production process increases breast cancer rates in postmenopausal women. Synthetic fibres like acrylonitrile also serve as breeding grounds for bacteria, which could cause skin conditions and general discomfort.

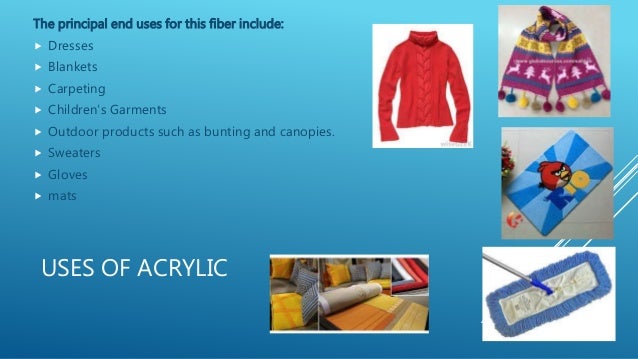

Uses of Acrylic Fabric

Articles made of acrylic fibres are easy to care for: they dry easily and, if properly set during manufacture, maintain their dimensions. All these properties gave this fibre many uses as follows:

Since acrylic fabric is designed to be similar to wool, it is used in many of the same applications as this highly popular natural fibre. For instance, apparel manufacturers make acrylic fibre into sweaters, mittens, gloves, pants, hoodies, and a variety of other types of cold-weather clothing. Additionally, acrylic is a popular material for carpeting, upholstery, rugs, and other traditionally wool-dominated homeware product categories.

While acrylic is highly similar to wool in its natural state, it can be made to resemble other fabrics, such as cotton, depending on the spinning mechanism that is used. Manufacturers can make types of acrylic that resemble fur, which can be useful for props or costumes.

Acrylic fibre is used as one of the constituents of carbon fibre, which is in high demand in industrial applications. Otherwise, however, acrylic fibre doesn’t have a lot of industrial applications; while this fabric is highly durable, its flammability makes it ineligible for use in many industrial environments.

One of the most prominent applications of acrylic fibre is in knitting. While most people who knit prefer wool for high-end products, many amateur knitters use acrylic as a “learner fibre” or as a yarn for cheap, low-effort projects. While there are significant detractors to using acrylic as a knitting material, its inability to lose its color and inexpensiveness afford it a valuable position within the knitting hobbyist market.

Other apparel uses such as wrinkle resistant fabrics, pile and fleece fabrics, children’s wear.

Outdoor end uses such as car tops, boat covers, awnings, outdoor furniture. Industrial end uses such as filtration materials, reinforcement materials in construction, car batteries

Disadvantages of acrylic:

extremely irresistant to abrasion

electrifies

unhygienic

flammable

- Knit Jersey, Sweater, blankets

- Wrinkle resistant fabrics.

- Pile and Fleece fabrics

- Carpets and rugs.

- Wash delicate items by hand in warm water. Static electricity may be reduced by using a fabric softener in every third or fourth washing. Gently squeeze out water, smooth or shake out garment and let dry on a non-rust hanger. (Sweaters, however, should be dried flat.)

- When machine washing, use warm water and add a fabric softener during the final rinse cycle.

- Machine dry at a low temperature setting. Remove garments from dryer as soon as tumbling cycle is completed.

- If ironing is required, use a moderately warm iron. (For specific instructions, refer to garment's sewn-in care label.)

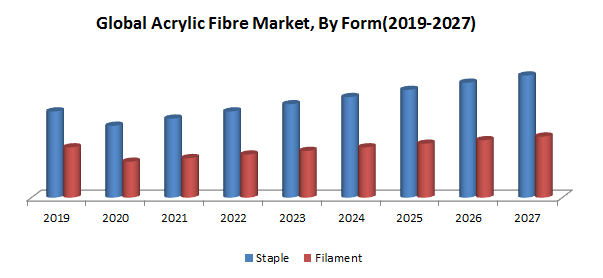

Key players operating in Global Acrylic Fibre Market

• Aksa Akrilik Kimya Sanayii A.Ş.

• Dralon

• Thai Acrylic Fiber Co.Ltd

• Polymir

• Taekwang Industrial Co. Ltd.

• Kaltex

• Indian Acrylics Limited

• Toray Industries, Inc.

• Ningbo Zhongxin Acrylic Fibers Co., Ltd

• W. Barnet GmbH & Co. KG

• Pasupati Acrylon Limited

• Formosa Plastic Group

• Zhejiang Hangzhouwan Acrylic Co., Ltd.

• Jilin Qifeng Chemical Fiber Co.Ltd

Global Acrylic Fibre Market, By Region

• North America • Europe • Asia Pacific • Middle East & Africa • South America