PRODUCTION MANAGEMENT

The concept of Production Management and its functions

Concept Of Production management refers to the application of management and principles to the production function in a factory. In simple words production management involves planning, organizing, directing and controlling in the production process.

The application of management to the field of production has been the result of at least three developments:

(i) First is the development of factory system of production. Until the emergence of the concept of manufacturing, there was no such thing as management as we know it. It is true that people operated business of one type or another, but for the most part, these people were owners of business and did not regard themselves as managers as well,

(ii) Essentially stems from the first, namely, the development of the large corporation with many owners and the necessity to hire people to operate the business,

(iii) Stems from the work of many of the pioneers of scientific management who were able to demonstrate the value, from a performance and profit point of view, of some of the techniques they were developing.

Definition of Production Management

“It is also called operations management, planning, and control of industrial processes to ensure that they move smoothly at the required level.

Production “Management deals with decision–making related to the production process. So that the resulting goods and services are produced in accordance with the quantitative specifications and demand schedule with minimum cost”.

Production Management refers to the application of management principles to the production function in a factory. In other words, production management involves application of planning, organizing, directing and controlling the production process.

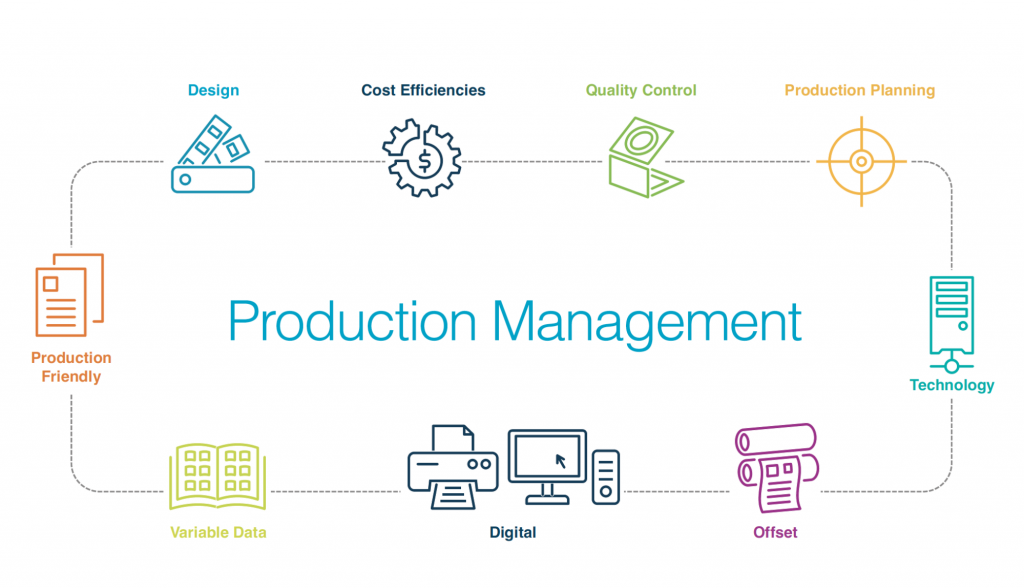

The main activities of production management can be listed as:

(i) procurement of input resources namely material, and land, labor, equipment, and capital.

(ii) Product design and development to determine the production process for transforming the input factors into the output of goods and services.

(iii) Supervision and control of the transformation process for the efficient production of goods and services.

characteristics of production management

1. Production Management is the process of effective planning

It helps in regulating the operations of that section of an enterprise which is responsible for the actual transformation of materials into finished products.

2. Related to the production process.

goods and services are produced in accordance with the quantitative specifications and demand schedule with minimum cost.

3. Production Management is a set of general principles for production

Production management has a set of certain principles like economies, facility design, job design, schedule design, quality control, inventory control, work study and cost, and budgetary control.

In short, the main activities of production management can be listed as:

(i) Specification and procurement of input resources namely management, material, and land, labour, equipment and capital.

(ii) Product design and development to determine the production process for transforming the input factors into output of goods and services.

(iii) Supervision and control of transformation process for efficient production of goods and services.

Scope of Production Management:

The scope of production management is indeed vast. Commencing with the selection of location, production management covers such activities as acquisition of land, constructing building, procuring and installing machinery, purchasing and storing raw materials and converting them into saleable products. Added to the above are other related topics such as quality management, maintenance management, production planning and control, methods improvement and work simplification and other related areas.

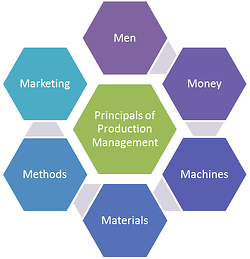

The components or functions of production management are as follows:

- Selection of Product and Design,

- Selection of Production Process,

- Selecting Right Production Capacity,

- Production Planning,

- Production Control,

- Quality and Cost Control,

- Inventory Control, and

- Maintenance and Replacement of Machines

The above functions of production management are briefly discussed below.

1. Selection of Product and Design

Production management first selects the right product for production. Then it selects the right design for the product. Care must be taken while selecting the product and design because the survival and success of the company depend on it. The product must be selected only after detailed evaluation of all the other alternative products. After selecting the right product, the right design must be selected. The design must be according to the customers' requirements. It must give the customers maximum value at the lowest cost. So, production management must use techniques such as value engineering and value analysis.

2. Selection of Production Process

Production management must select the right production process. They must decide about the type of technology, machines, material handling system, etc.

3. Selecting Right Production Capacity

Production management must select the right production capacity to match the demand for the product. This is because more or less capacity will create problems. The production manager must plan the capacity for both short and long term's production. He must use break-even analysis for capacity planning.

4. Production Planning

Production management includes production planning. Here, the production manager decides about the routing and scheduling.

Routing means deciding the path of work and the sequence of operations. The main objective of routing is to find out the best and most economical sequence of operations to be followed in the manufacturing process. Routing ensures a smooth flow of work.

Scheduling means to decide when to start and when to complete a particular production activity.

5. Production Control

Production management also includes production control. The manager has to monitor and control the production. He has to find out whether the actual production is done as per plans or not. He has to compare actual production with the plans and finds out the deviations. He then takes necessary steps to correct these deviations.

6. Quality and Cost Control

Production management also includes quality and cost control. Quality and Cost Control are given a lot of importance in today's competitive world. Customers all over the world want good-quality products at cheapest prices. To satisfy this demand of consumers, the production manager must continuously improve the quality of his products. Along with this, he must also take essential steps to reduce the cost of his products.

7. Inventory Control

Production management also includes inventory control. The production manager must monitor the level of inventories. There must be neither over stocking nor under stocking of inventories.

If there is an overstocking, then the working capital will be blocked, and the materials may be spoiled, wasted or misused.

If there is an understocking, then production will not take place as per schedule, and deliveries will be affected.

8. Maintenance and Replacement of Machines

Production management ensures proper maintenance and replacement of machines and equipments. The production manager must have an efficient system for continuous inspection (routine checks), cleaning, oiling, maintenance and replacement of machines, equipments, spare parts, etc. This prevents breakdown of machines and avoids production halts.

What’s the Aim of Production Function?

The goal of production function is to add value. Be it product or services; the idea is to create something that will strengthen the relationship between the organization and customers. But this cannot only be made possible by the production department.

The marketing people also have a huge role to play in this. They are the ones that will distribute the product to potential buyers and should have the capacity to inform the production department of what customers or consumers would prefer.

Why Production Management is so Important

Production management is relevant to the firm’s success in many ways. Used efficiently, it can lead to numerous accomplishments which will take the business to a great height. Below is the importance of production management.

- Helps the Firm to Accomplish its Objectives

Production management helps the firm to achieve its sales and business objectives by producing goods and services that meet the need of consumers. Sales and profit will increase if the product produced satisfies the customers’ needs.

- Boost Business Reputation and Goodwill

A satisfied customer will undoubtedly want to repeat patronage. That’s why businesses should ensure that quality products are delivered continuously. Making sure that your customers are always happy can also boost business reputation.

- Reduces the Cost of Production

Production management ensures that resources are used judiciously, without compromising on quality. In other words, the business will continue to deliver quality products and sell at a convenient price to customers. But this can only be possible in a situation where the input and output are maximized.

Read a blog related in Production Management in the UK.

ReplyDeleteNice blog! Your blog is very informative. FOURFRONT PARTNERS is full-cycle Product Management service offering based in Washington, DC.

ReplyDeleteFOURFRONT PARTNERS