Alginate Fibre

Alginate is a natural polymer that exists widely in many species of

brown seaweed. The biological function of alginates is to give strength

and flexibility to the algal tissue and regulate the water content in

the seaweed. It is these properties along with the ability to produce

fibres from its isomers, which make Alginate the ideal wound dressing.

This based study set out to establish whether branan ferulate--a

polysaccharide compound available in gels could be successfully added to

the fibre of an alginate dressing to provide a superior wound-care

dressing.

INTRODUCTION

Alginate was first produced from seaweed in 1940. It is a product of a neutralizing reaction between alginic acid and caustic soda. It is non-flammable. When combined with other fibres, it takes on a sheer appearance. The raw material for the production of calcium alginate fibres is alginic acid, a compound that is obtained from the marine brown algae. The first scientific reports on the extraction of alginates from brown algae were presented towards the close of the nineteenth century by the chemist E.C. Stanford. He observed that alginates posses a variety of properties, including the ability to stabilize viscous suspensions, to form film layers, and to turn into gels. Although he saw opportunities for various potential applications, it was fifty years before industrial production actually started on a reasonable scale. Today, thousands of tons of alginates are produced per year for a wide variety of uses. They are in particular employed as gelling agent in food industry, so that the safety of alginates as food additive is established through many years of usage in this purpose.

Chemically, alginate is a polymeric acid, composed of two monomer units

INTRODUCTION

Alginate was first produced from seaweed in 1940. It is a product of a neutralizing reaction between alginic acid and caustic soda. It is non-flammable. When combined with other fibres, it takes on a sheer appearance. The raw material for the production of calcium alginate fibres is alginic acid, a compound that is obtained from the marine brown algae. The first scientific reports on the extraction of alginates from brown algae were presented towards the close of the nineteenth century by the chemist E.C. Stanford. He observed that alginates posses a variety of properties, including the ability to stabilize viscous suspensions, to form film layers, and to turn into gels. Although he saw opportunities for various potential applications, it was fifty years before industrial production actually started on a reasonable scale. Today, thousands of tons of alginates are produced per year for a wide variety of uses. They are in particular employed as gelling agent in food industry, so that the safety of alginates as food additive is established through many years of usage in this purpose.

Chemically, alginate is a polymeric acid, composed of two monomer units

L-guluronicacid(G

D- mannuronic acid (M)

D- mannuronic acid (M)

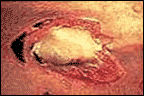

Sloughy pressure ulcer wound

High G Alginates:

For the High-G calcium alginate fibres (extracted from the stems of the seaweed), the calcium binding ability of the fibre is strong and the ion exchange process between the fibre and the wound exudates is slow. High-G calcium fibres are therefore less absorbent than High-M calcium fibres.

High M Alginates:

For fibres made from a High-M alginate (extracted from the leaf fronds of the seaweed), the calcium ions in the fibres are more easily replaced by sodium ions and the fibres swell easily in wound exudates

▪ Have increased absorbency

▪ Transport excess exudates away from the wound surface

▪ Be self adhesive to provide mechanical and microbial protection

▪ Be anti-microbial (e.g. silver)

▪ Enable tissue cleansing and scar reduction

▪ Be fibre free

▪ To include other additives, e.g. chitosan, aloe vera, zinc and antibiotics

The dressings are composed of calcium and sodium alginate fibres, which have been entangled to form a strong cohesive product .This produces a highly absorbent, n-adherent dressing that transmits oxygen and moisture vapour .In the presence of exudate, the fibres form a hydrophilic gel .

Interactive: They produce an environment above the wound, which allows optimal healing

Bioactive : they intervene in the healing process by promoting optimal conditions for wound healing.

METHOD:

A wet extruder was used to produce the fibres. The effect of spinning-bath calcium chloride concentration (used as the coagulant in the fibre-spinning process) on the tensile and absorption properties of alginate fibres containing 25% w/w branan ferulate are examined. Sodium alginate and branan ferulate were separately dissolved in de-ionized water and then stirred together to make up a 5% dope solution. The dope was then forced through a spinneret and into the calcium chloride bath, where fibres were precipitated and then carried over the first set of rollers. The fibres were washed in the next bath and drawn at different rates to enhance their tensile properties. At the 'winding-up' stage the filaments were either passed over a contact heater and into a furnace (dry pick-up) or transferred into acetone baths of increasing concentrations of 50, 80 and 100% aqueous acetate to remove the water (wet pick-up). The moisture content of standard alginate fibres and those with branan ferulate were measured and compared. Breaking load, tenacity and breaking extension and the quantity of branan ferulate in the fibres were also measured. The process was repeated four times, using different strengths of calcium chloride. Using various draw ratios, the effects of liquid uptake were measured using water, saline and a solution called A (to mimic human blood and exudates-type fluids). Out of the four calcium chloride concentrations used, 1% concentration appeared to give the highest and most conclusive results for fibre-breaking load, tenacity and breaking extension.

For the High-G calcium alginate fibres (extracted from the stems of the seaweed), the calcium binding ability of the fibre is strong and the ion exchange process between the fibre and the wound exudates is slow. High-G calcium fibres are therefore less absorbent than High-M calcium fibres.

High M Alginates:

For fibres made from a High-M alginate (extracted from the leaf fronds of the seaweed), the calcium ions in the fibres are more easily replaced by sodium ions and the fibres swell easily in wound exudates

▪ Have increased absorbency

▪ Transport excess exudates away from the wound surface

▪ Be self adhesive to provide mechanical and microbial protection

▪ Be anti-microbial (e.g. silver)

▪ Enable tissue cleansing and scar reduction

▪ Be fibre free

▪ To include other additives, e.g. chitosan, aloe vera, zinc and antibiotics

The dressings are composed of calcium and sodium alginate fibres, which have been entangled to form a strong cohesive product .This produces a highly absorbent, n-adherent dressing that transmits oxygen and moisture vapour .In the presence of exudate, the fibres form a hydrophilic gel .

Interactive: They produce an environment above the wound, which allows optimal healing

Bioactive : they intervene in the healing process by promoting optimal conditions for wound healing.

METHOD:

A wet extruder was used to produce the fibres. The effect of spinning-bath calcium chloride concentration (used as the coagulant in the fibre-spinning process) on the tensile and absorption properties of alginate fibres containing 25% w/w branan ferulate are examined. Sodium alginate and branan ferulate were separately dissolved in de-ionized water and then stirred together to make up a 5% dope solution. The dope was then forced through a spinneret and into the calcium chloride bath, where fibres were precipitated and then carried over the first set of rollers. The fibres were washed in the next bath and drawn at different rates to enhance their tensile properties. At the 'winding-up' stage the filaments were either passed over a contact heater and into a furnace (dry pick-up) or transferred into acetone baths of increasing concentrations of 50, 80 and 100% aqueous acetate to remove the water (wet pick-up). The moisture content of standard alginate fibres and those with branan ferulate were measured and compared. Breaking load, tenacity and breaking extension and the quantity of branan ferulate in the fibres were also measured. The process was repeated four times, using different strengths of calcium chloride. Using various draw ratios, the effects of liquid uptake were measured using water, saline and a solution called A (to mimic human blood and exudates-type fluids). Out of the four calcium chloride concentrations used, 1% concentration appeared to give the highest and most conclusive results for fibre-breaking load, tenacity and breaking extension.

CHEMICAL STRUCTURE AND PROCESS OF GEL FORMATION

Cell walls of brown algae contain algin, a compound that mainly consists of alginic acid and its salts. Alginic acid is a linear polysaccharide made from two different monomer subunits. The monomers are mannuronate and guluronate, the gel-forming properties of the respective alginates are mainly determined by the proportional content and distribution of these two components.

The ratio of mannuronic acid to guluronic acid may vary to a certain extent, depending on the origin and species of the algae, the part of the plant utilized, and also on the season of harvesting. Through careful selection of the algae feedstock it is, nevertheless, possible to produce alginates of always constant properties. The manufacturing process of alginates involves crushing and washing of the raw material and dissolution of the extracted sodium alginate in water. A viscous solution is obtained which is extruded into a calcium chloride bath. Here, the sodium ions are replaced by calcium ions and the insoluble calcium alginate is precipitated. Rinsing and dehydration then leads to the production of a textile fibre.

The fibres which are used contain a di- or higher valent cation which is effective for cross-linking the hydrogel. Examples of suitable cations include Ca2+, Zn2+, and cations which also act as enzyme cofactors. Particular preferred examples of fibres which may be used are calcium alginate fibres. The fibres will generally have a length of 1 to 80 mm and a thickness of 10 to 50 microns. The fibres may be such that they absorb water from the aqueous solution of the hydrogel precursor material during manufacture of the dehydrated hydrogel.

When the dressing is applied to a wound, the reverse ion exchange takes place. The calcium alginate fibres are placed on the wound in a dry state and begin to absorb the exudates. In this respect their action is comparable to that of a conventional textile dressing material. The calcium ions are then gradually exchanged against sodium ions that are present in the blood and wound exudates. The fibres absorb large amounts of secretions, start to swell and in the presence of sodium ions turn into a moist gel that fills and securely covers the wound. Both the extent and the rate of gel formation depend on the available amounts of secretions. The more exudates present, the more rapid can gel formation occur. Addition of excess sodium ions causes further dissolution of the gel, so that calcium alginate fibres remaining in the wound can be resorbed if necessary, but may also without problems be rinsed out with physiological saline solution.

Algae are of an enormous ecological and economic significance. Of greatest importance is their capability to convert solar energy into chemical energy via photosynthesis, it is this primary production that constitutes the basis for all animal life in aqueous environments. Algae that are rich in protein and vitamins have since long been serving as nutrients in many coastal regions, but their direct use is out of proportion to the role of algae as raw material in food, forage and fertilizers industry. Industrial production of gelling and mucigenous agents does mainly occur from red and brown algae. The largest and most developed species can be found among the marine brown algae. Except for some floating species, brown algae are usually found in coastal regions, growing in the sea in enormous submerged forests. They are harvested with special vessels, following strict ecological directions to save and ensure the stocks.

The physical and chemical properties of the dressings depend upon the content of calcium and sodium ions and the relative concentration and arrangement of the mannuronic and guluronic monomers. Dressings rich in mannuronic acid tend to react readily with sodium ions, forming soft amorphous gels. Dressings rich in guluronic acid gel less readily and form firmer less mobile gels.

PROPERTIES OF SORBALGON

Sorbalgon consists primarily of fibres of calcium alginate rich in mannuronic acid. Sorbalgon is a supple, non-woven dressing made from high-quality calcium alginate fibres with excellent gel-forming properties. The dressing offers a number of practical therapeutic advantages for wound healing over any other commonly used textile mater. Calcium alginate is insoluble in water but in the presence of sodium ions from wound exudates, a partial ion exchange reaction takes place resulting in the production of sodium alginate which forms a hydrophilic gel on the wound surface that is believed to facilitate healing.

CAPACITY AND MECHANISM OF ABSORPTION

Sorbalgon dressings absorb approx. 10 ml exudates per gram dry weight and are thus provided with a very high absorption capacity. They in addition differ from textile dressings with respect to the applied mechanism of absorption. Whereas cotton gauze holds the absorbed fluid mainly between the fibres, the calcium alginates take up wound secretions directly into the fibres, i.e. using intracapillary forces. Germs and detritus are retained within the gel structure as the fibres swell during subsequent gelatinization. The wound is thus effectively cleansed and a considerable reduction of micro-organisms can be attained. Intracapillary absorption of exudates along with swelling and gelatinization does, however, not affect the fundamental permeability of the dressing for moisture. The gel remains permeable to gas so that Sorbalgon represents a dressing material that facilitates a permeable moist wound treatment, in contrast to an occlusive moist wound treatment e.g. with hydrocolloids. This is especially important in infected wounds where air penetration reduces the risk of dangerous infections with anaerobic bacteria.

Cell walls of brown algae contain algin, a compound that mainly consists of alginic acid and its salts. Alginic acid is a linear polysaccharide made from two different monomer subunits. The monomers are mannuronate and guluronate, the gel-forming properties of the respective alginates are mainly determined by the proportional content and distribution of these two components.

The ratio of mannuronic acid to guluronic acid may vary to a certain extent, depending on the origin and species of the algae, the part of the plant utilized, and also on the season of harvesting. Through careful selection of the algae feedstock it is, nevertheless, possible to produce alginates of always constant properties. The manufacturing process of alginates involves crushing and washing of the raw material and dissolution of the extracted sodium alginate in water. A viscous solution is obtained which is extruded into a calcium chloride bath. Here, the sodium ions are replaced by calcium ions and the insoluble calcium alginate is precipitated. Rinsing and dehydration then leads to the production of a textile fibre.

The fibres which are used contain a di- or higher valent cation which is effective for cross-linking the hydrogel. Examples of suitable cations include Ca2+, Zn2+, and cations which also act as enzyme cofactors. Particular preferred examples of fibres which may be used are calcium alginate fibres. The fibres will generally have a length of 1 to 80 mm and a thickness of 10 to 50 microns. The fibres may be such that they absorb water from the aqueous solution of the hydrogel precursor material during manufacture of the dehydrated hydrogel.

When the dressing is applied to a wound, the reverse ion exchange takes place. The calcium alginate fibres are placed on the wound in a dry state and begin to absorb the exudates. In this respect their action is comparable to that of a conventional textile dressing material. The calcium ions are then gradually exchanged against sodium ions that are present in the blood and wound exudates. The fibres absorb large amounts of secretions, start to swell and in the presence of sodium ions turn into a moist gel that fills and securely covers the wound. Both the extent and the rate of gel formation depend on the available amounts of secretions. The more exudates present, the more rapid can gel formation occur. Addition of excess sodium ions causes further dissolution of the gel, so that calcium alginate fibres remaining in the wound can be resorbed if necessary, but may also without problems be rinsed out with physiological saline solution.

Algae are of an enormous ecological and economic significance. Of greatest importance is their capability to convert solar energy into chemical energy via photosynthesis, it is this primary production that constitutes the basis for all animal life in aqueous environments. Algae that are rich in protein and vitamins have since long been serving as nutrients in many coastal regions, but their direct use is out of proportion to the role of algae as raw material in food, forage and fertilizers industry. Industrial production of gelling and mucigenous agents does mainly occur from red and brown algae. The largest and most developed species can be found among the marine brown algae. Except for some floating species, brown algae are usually found in coastal regions, growing in the sea in enormous submerged forests. They are harvested with special vessels, following strict ecological directions to save and ensure the stocks.

The physical and chemical properties of the dressings depend upon the content of calcium and sodium ions and the relative concentration and arrangement of the mannuronic and guluronic monomers. Dressings rich in mannuronic acid tend to react readily with sodium ions, forming soft amorphous gels. Dressings rich in guluronic acid gel less readily and form firmer less mobile gels.

PROPERTIES OF SORBALGON

Sorbalgon consists primarily of fibres of calcium alginate rich in mannuronic acid. Sorbalgon is a supple, non-woven dressing made from high-quality calcium alginate fibres with excellent gel-forming properties. The dressing offers a number of practical therapeutic advantages for wound healing over any other commonly used textile mater. Calcium alginate is insoluble in water but in the presence of sodium ions from wound exudates, a partial ion exchange reaction takes place resulting in the production of sodium alginate which forms a hydrophilic gel on the wound surface that is believed to facilitate healing.

CAPACITY AND MECHANISM OF ABSORPTION

Sorbalgon dressings absorb approx. 10 ml exudates per gram dry weight and are thus provided with a very high absorption capacity. They in addition differ from textile dressings with respect to the applied mechanism of absorption. Whereas cotton gauze holds the absorbed fluid mainly between the fibres, the calcium alginates take up wound secretions directly into the fibres, i.e. using intracapillary forces. Germs and detritus are retained within the gel structure as the fibres swell during subsequent gelatinization. The wound is thus effectively cleansed and a considerable reduction of micro-organisms can be attained. Intracapillary absorption of exudates along with swelling and gelatinization does, however, not affect the fundamental permeability of the dressing for moisture. The gel remains permeable to gas so that Sorbalgon represents a dressing material that facilitates a permeable moist wound treatment, in contrast to an occlusive moist wound treatment e.g. with hydrocolloids. This is especially important in infected wounds where air penetration reduces the risk of dangerous infections with anaerobic bacteria.

TAMPONING PROPERTIES AND CONFORMABILITY

A good adaptation of the dressing to the wound surface is necessary for the absorption of exudates, bacteria, detritus, and other impurities. Whereas smooth wound surfaces usually allow sufficient contact without any problem even for common wound dressings, proper wound treatment using these materials is often difficult in deep and lacerated wounds. The calcium alginate dressing Sorbalgon solves this problem even under extremely difficult wound conditions. The dressing is not woven, but rather consists of a supple, fibrous mat that has excellent shaping and packing capabilities. When the fibres swell during gelatinisation and finally fill out the wound, a close contact to the wound floor is generated even in the almost inaccessible areas, absorption of wound exudates, thus being ensured even at the deepest points of the wound.

A good adaptation of the dressing to the wound surface is necessary for the absorption of exudates, bacteria, detritus, and other impurities. Whereas smooth wound surfaces usually allow sufficient contact without any problem even for common wound dressings, proper wound treatment using these materials is often difficult in deep and lacerated wounds. The calcium alginate dressing Sorbalgon solves this problem even under extremely difficult wound conditions. The dressing is not woven, but rather consists of a supple, fibrous mat that has excellent shaping and packing capabilities. When the fibres swell during gelatinisation and finally fill out the wound, a close contact to the wound floor is generated even in the almost inaccessible areas, absorption of wound exudates, thus being ensured even at the deepest points of the wound.

HANDLING OF SORBALGON

Depending on the wound conditions, wound toilet occurs via surgical or enzymatic measures or through local disinfection. Sorbalgon is then applied to the wound in a dry state. A number of overlapping dressings can be used without problems when a larger wound area has to be covered. Deep and lacerated wounds should be loosely packed. A method that proved efficient in the treatment of infected wounds is the addition of microbicidal agents. Aspects of tissue tolerance should be taken into account when choosing appropriate antiseptics. When Tamponing with Sorbalgon should for technical reasons be continued in wounds with declining secretion, the dressing can be moistened with Ringers solution. Rinsing of the calcium alginate fibres does not result in gelatinisation, the dressing is still capable of absorbing exudates and promoting the ion exchange that induces gel formation. The dressing will also not adhere to dry wounds when it is impregnated with Ringers solution.

Sorbalgon can be secured in the normal manner with conforming bandages, gauze dressings, or nonwoven elastic bandages, e.g. Omnifix. Application of dressing retentions is, however, not strictly necessary, and can be omitted at sites that are difficult to bandage, as e.g. in facial wounds. When the dressing has to be renewed the gelatinous dressing pad is removed with forceps. Fibres that possibly remain in the wound are quite safe as they will gradually dissolve in wound secretions. The gelatinous dressing may also be rinsed out with Ringers solution.

The frequency of dressing changes depends on the individual situation of the wound. During the phase of wound cleansing replacements may be necessary once or twice daily, according to the production of exudates. Later, with the onset of proliferation, it may be sufficient to renew the dressing every two to three days.

Depending on the wound conditions, wound toilet occurs via surgical or enzymatic measures or through local disinfection. Sorbalgon is then applied to the wound in a dry state. A number of overlapping dressings can be used without problems when a larger wound area has to be covered. Deep and lacerated wounds should be loosely packed. A method that proved efficient in the treatment of infected wounds is the addition of microbicidal agents. Aspects of tissue tolerance should be taken into account when choosing appropriate antiseptics. When Tamponing with Sorbalgon should for technical reasons be continued in wounds with declining secretion, the dressing can be moistened with Ringers solution. Rinsing of the calcium alginate fibres does not result in gelatinisation, the dressing is still capable of absorbing exudates and promoting the ion exchange that induces gel formation. The dressing will also not adhere to dry wounds when it is impregnated with Ringers solution.

Sorbalgon can be secured in the normal manner with conforming bandages, gauze dressings, or nonwoven elastic bandages, e.g. Omnifix. Application of dressing retentions is, however, not strictly necessary, and can be omitted at sites that are difficult to bandage, as e.g. in facial wounds. When the dressing has to be renewed the gelatinous dressing pad is removed with forceps. Fibres that possibly remain in the wound are quite safe as they will gradually dissolve in wound secretions. The gelatinous dressing may also be rinsed out with Ringers solution.

The frequency of dressing changes depends on the individual situation of the wound. During the phase of wound cleansing replacements may be necessary once or twice daily, according to the production of exudates. Later, with the onset of proliferation, it may be sufficient to renew the dressing every two to three days.

WOUNDS FOLLOWING TUMOR SURGERY

The irregular wound surfaces or exposed position of the wound bed cannot be provided with temporary covers from skin substitutes, also re-present a suitable field of application for Sorbalgon. An extensive clinical study on wound treatment with calcium alginate dressings produced without exception excellent conditioning results. Because of their extraordinary suppleness and conformability, calcium alginates are, in addition, indicated in those cases where wound management with common materials is found to be extremely difficult due to the exposed location of the injury or where the situation of the patient demands maximal pain reduction: e.g. wounds at the fingers, toes, or facial wounds, following nail removal, or tooth extraction.

The irregular wound surfaces or exposed position of the wound bed cannot be provided with temporary covers from skin substitutes, also re-present a suitable field of application for Sorbalgon. An extensive clinical study on wound treatment with calcium alginate dressings produced without exception excellent conditioning results. Because of their extraordinary suppleness and conformability, calcium alginates are, in addition, indicated in those cases where wound management with common materials is found to be extremely difficult due to the exposed location of the injury or where the situation of the patient demands maximal pain reduction: e.g. wounds at the fingers, toes, or facial wounds, following nail removal, or tooth extraction.

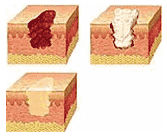

HYDROGELS

Hydrogel dressings contain a large proportion of water - often more than 70-90 per cent. Nu-Gel and Purilon are hydrogel/alginate combinations. Hydrogels have many of the characteristics of an "ideal" dressing, (eg, they promote moist healing, and are non-adherent). They can cool the surface of the wound and this is said to be the cause of the marked reduction in pain that is reported in patients using these dressings. Sometimes Hydrogels are refrigerated to increase this effect. Hydrogels are suitable for use on dry "sloughy" or necrotic wounds and for lightly exuding wounds. They are suitable for use for all stages of wound healing except for infected or heavily-exuding wounds. Most hydrogels require covering with a secondary dressing. A recent innovation has been an extension to the range of gel formulations available - there are now six gels. They are an excellent alternative to chlorinated solutions such as Eusol for desloughing wounds. Intrasite gel sachet has been replaced by a user-friendly "applipak" dispenser in two sizes.

Hydrogel dressings contain a large proportion of water - often more than 70-90 per cent. Nu-Gel and Purilon are hydrogel/alginate combinations. Hydrogels have many of the characteristics of an "ideal" dressing, (eg, they promote moist healing, and are non-adherent). They can cool the surface of the wound and this is said to be the cause of the marked reduction in pain that is reported in patients using these dressings. Sometimes Hydrogels are refrigerated to increase this effect. Hydrogels are suitable for use on dry "sloughy" or necrotic wounds and for lightly exuding wounds. They are suitable for use for all stages of wound healing except for infected or heavily-exuding wounds. Most hydrogels require covering with a secondary dressing. A recent innovation has been an extension to the range of gel formulations available - there are now six gels. They are an excellent alternative to chlorinated solutions such as Eusol for desloughing wounds. Intrasite gel sachet has been replaced by a user-friendly "applipak" dispenser in two sizes.

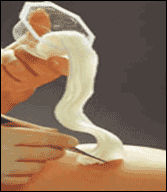

Applying Nu-Gel, one of the combination hydrogel/alginate products

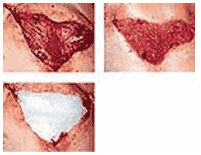

Melgisorb cavity dressing

Melgisorb cavity dressingOne of the newer alginate dressings

PHYSIOLOGICAL SAFETY

Sorbalgon is free of medicated additives and is especially well tolerated even during long-term application. Sorbalgon may be impregnated with aqueous solutions, e.g. with Ringers solution or microbicidal agents, and serve as carrier for these substances. In this context, it is again especially helpfull that difficult to approach wound areas can easily be reached with tamponades of the calcium alginate dressing. Alginates are easily removed from the wound with saline, regardless of the type of alginate used. Alginates those are rich in mannuronic acid (e.g. Sorbsan) from a soft and flexible gel that is dissolved with saline and easily washed out of the wound. Alginates that are rich in guluronic acid, however, tend to form a firmer gel, which is removed from the wound intact and should be soaked well with saline before removal.

CONCLUSION

Alginate fibre will employ active fabrics that do not require work from the human body to provide their benefits. Fusion between fibre science and space technologies, optics, and pharmacy will be inevitable in the coming future. The fibres will encompass numerous platforms still untapped and hidden. The emphasis will be again towards fibres which will replicate the natural functions in minute details. Greater stress will be laid on quality products than quantity and the industries must gear up to adopt it to the new found dynamism of market economy.

No comments:

Post a Comment