Maintenance Tools & Techniques

Not

every maintenance tool fits on a tool belt, and not every maintenance

tool is designed

for repairing assets. O+ther tools exist that help

maintenance teams improve things beyond

physical assets. For instance,

various types of analyses are used to gather insights about

why and when

assets fail. And standards, regulations, and other documentation exist

to

keep maintenance teams organized and compliant.

Using these maintenance tools will help you build an environment in which proactive

maintenance and precision maintenance can thrive.

Analysis

P-F Curve

A

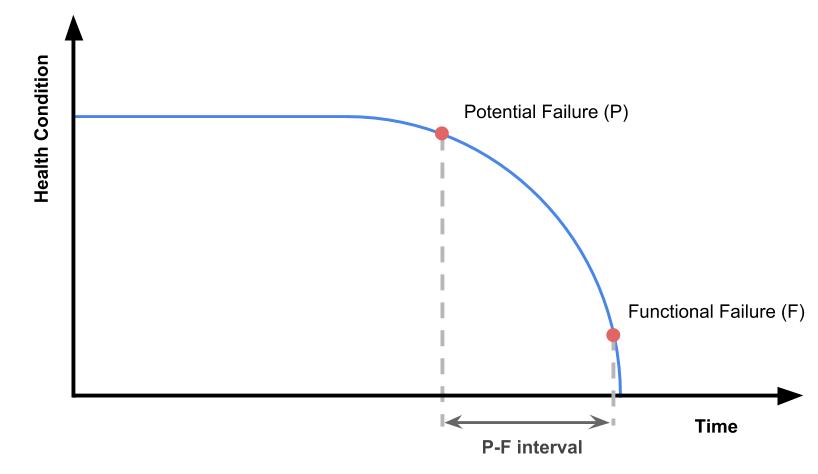

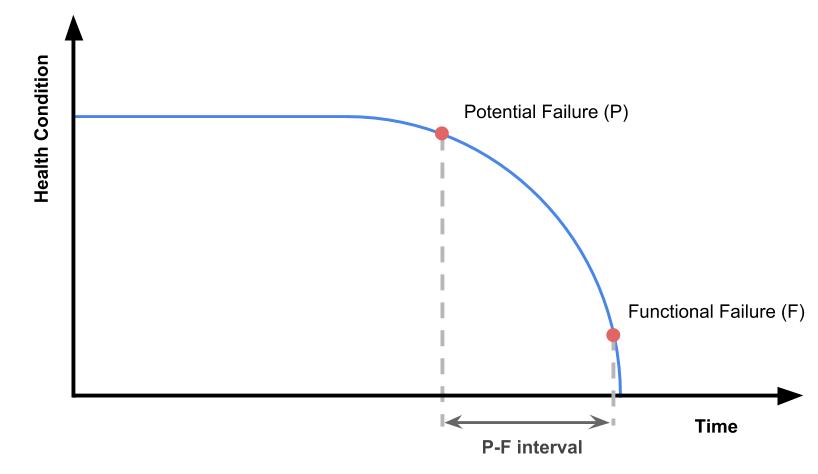

P-F curve is a graph that shows the health of equipment over time to

identify the

interval between potential failure and functional failure.

P-F Curve

What is a P-F curve?

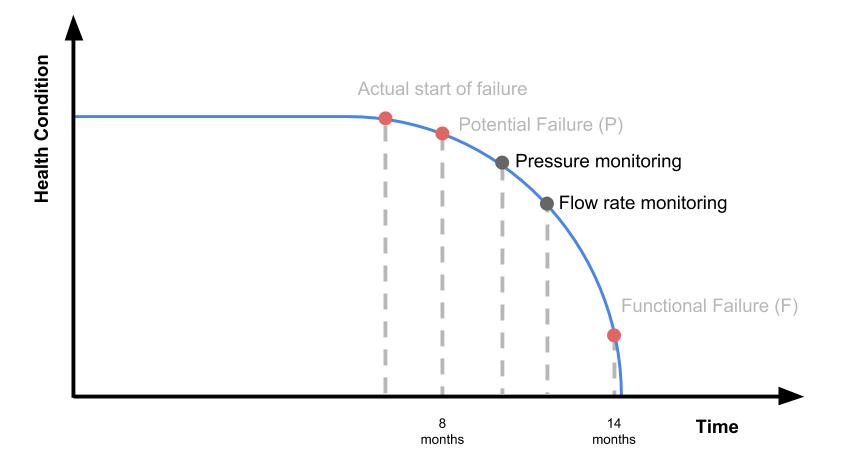

A P-F curve is a graph that shows the health of equipment over time to identify theinterval between potential failure and functional failure.

Overview

The eventual failure of any equipment is inevitable. Wear and tear naturally occur withcontinual usage. In the same way your pair of shoes

eventually get worn out after

500 miles of walking, your key plant

equipment (e.g. pumps, motor bearings)

will ultimately reach its

functional failure point.

The good news is that the functional failure point (i.e. the end of equipment life) takes

The good news is that the functional failure point (i.e. the end of equipment life) takes

a long time to

occur. The P-F curve helps to characterize the behavior of equipment

over time. Its used to assess the maximum usage that can be gained from

the equipment.

Potential failure and functional failure

There are two main points of the P-F curve that need to be identified.- Potential failure indicates the point at which we notice that equipment is starting to deteriorate and fail.

- Functional failure is the point at which equipment has reached its useful limit and is no longer operational.

is initially noticed and when the equipment fails completely.

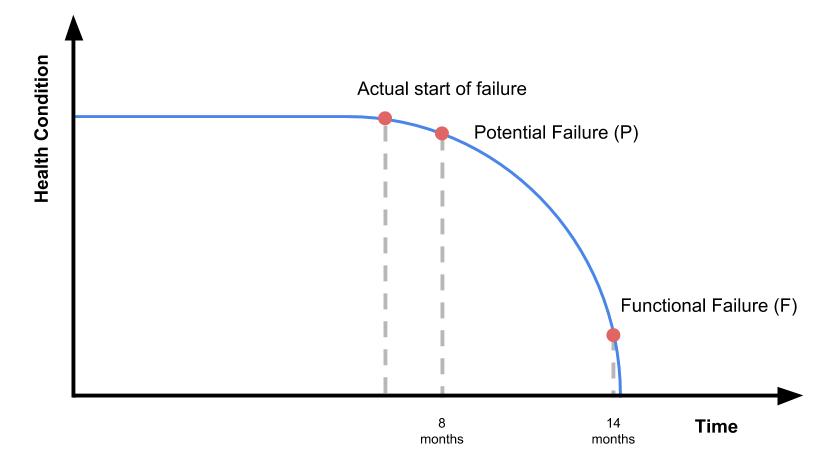

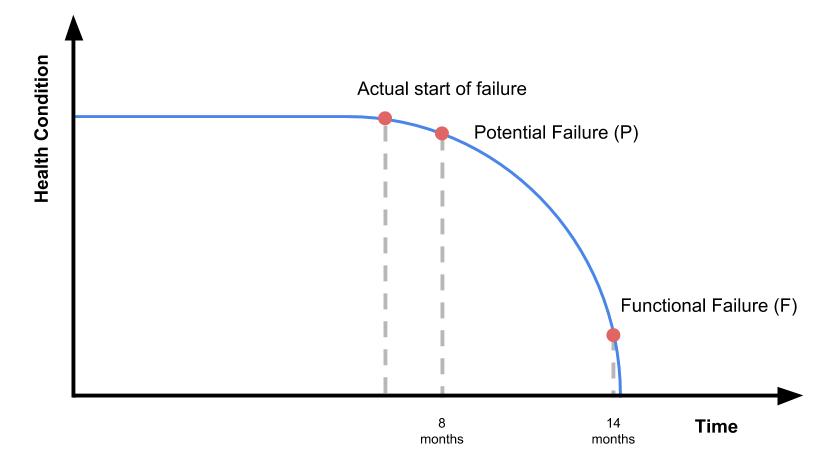

For example, assume that a pump that’s been normally operating for eight months suddenly produces more noise than usual. Unnecessary noise can be a sign of failure. With the inspection and confirmation of maintenance personnel, we can then say that the first noticed sign of failure (i.e. the potential failure point) occurred at eight months.

Note that the actual start of deterioration might have happened before the eight-month mark. So we can assume that the actual start of failure happened some time before point P. However, it is only the potential point of failure that we can measure in time with certainty as it was the first event when noticeable symptoms of failure were recorded.

For the same example, we can suppose that the pump continues to operate for another six months until it totally breaks down—that is the functional failure point at 14 months.

Common practice is to maximize the use of the P-F curve with condition-based maintenance (CBM). By applying CBM and proactively checking the condition of the equipment, we are able to infer the rate of deterioration over time. Maintenance personnel are then able to plan and assess whether it is cost-efficient to mitigate the causes of failure given the projected P-F interval.

How to create a P-F curve

The basic parts of the P-F curve are given above. Actual data can be expected to vary on a case to case basis. For instance, the lifespan of a heavy duty pump might not be the same as that of a mechanical bandsaw. It then follows that expected failure points for different equipment will vary. Care must be considered when building P-F curves. Different types of equipment are expected to have varying interval values.For example, assume that a pump that’s been normally operating for eight months suddenly produces more noise than usual. Unnecessary noise can be a sign of failure. With the inspection and confirmation of maintenance personnel, we can then say that the first noticed sign of failure (i.e. the potential failure point) occurred at eight months.

Note that the actual start of deterioration might have happened before the eight-month mark. So we can assume that the actual start of failure happened some time before point P. However, it is only the potential point of failure that we can measure in time with certainty as it was the first event when noticeable symptoms of failure were recorded.

For the same example, we can suppose that the pump continues to operate for another six months until it totally breaks down—that is the functional failure point at 14 months.

How to maximize the P-F curve

Now that we’ve visualized how the P-F curve relates to real-life scenarios, we have the chance to prepare for the inevitable functional failure. The idea is to balance our resources to prolong the P-F interval economically.Common practice is to maximize the use of the P-F curve with condition-based maintenance (CBM). By applying CBM and proactively checking the condition of the equipment, we are able to infer the rate of deterioration over time. Maintenance personnel are then able to plan and assess whether it is cost-efficient to mitigate the causes of failure given the projected P-F interval.

The P-F curve and CBM

At the early signs of failure, it may be helpful to perform routine CBM tasks to assess the health of the equipment.Continuing with our pump example, a P-F curve coupled with CBM tasks to monitor pressure and flow rate conditions may resemble the following graph:

A maintenance team can attach condition monitoring sensors to the equipment after the point of

- potential failure to assess how much more the equipment can be maximized.

FMEA

Failure

Mode and Effects Analysis (FMEA) is a process that is available to

organizations to identify

potential failures with assets and other areas

of business.

FMEA is the

systematic process to evaluate failure modes, causes associated with

failures and the

effect of such failures. The cross functional core

committee needs to identify known and potential

areas of failure and the

root-causes of such failure through why–why analysis. Brainstorming

through small group activities may be carried out involving the

frontline supervisors and even

operators. The failure modes can be

prioritised by assigning Risk Priority Number (RPN), which

is a product

of occurrence (frequency of failure O), severity (seriousness of the

failures S) and

detection (ability to detect the failure D).

RPN = O x S x D

Details of the failure analysis need to be documented.

Acronym for Failure Modes and Effects Analysis. FMEA is a risk

assessment tool, that evaluates the RPN = O x S x D

Details of the failure analysis need to be documented.

severity, occurrence and detection

of risks to prioritize which ones are the most urgent. The two most

popular types of FMEAs are Process (PFMEA) and Design (DFMEA).

Each category has a scoring matrix with a 1-10 scale.

After scoring of each category is complete for each risk, the three scores are multiplied together

Each category has a scoring matrix with a 1-10 scale.

- Severity of 1 denotes low risk to the end customer, & a score of 10 denotes high risk to the customer.

- Occurrence of 1 denotes low probability of the risk happening, and a 10 denotes a very high probability of the risk happening.

- Detection of 1 denotes a process that WILL likely catch a failure, and a 10 means the process will likely NOT catch a failure.

After scoring of each category is complete for each risk, the three scores are multiplied together

(Severity x Occurrence x Detection) to

determine the Risk Priority Number (RPN). The RPNs

are sorted from largest to smallest, and actions are taken on the top risks in order to reduce the

overall risk.

Typically, the severity cannot be reduced, so the team should

evaluate ways to reduce occurrence

or increase detection. After actions

are completed, the RPNs are recalculated and new risks

are determined.

Root Cause Analysis

Root cause analysis (RCA) is a systematic process of identifying the origin of an incident.

Next to defining a problem

accurately, root cause analysis is one of the most important elements of

problem-solving in quality management. That’s because if you’re not aiming at

the right target,

you’ll never be able to eliminate the real problem that’s

hurting quality.

So which type of root cause analysis

tool is the best one to use? Manufacturers have a range of methods

at their

fingertips, each of which is appropriate for different situations. Below we

discuss five common

root cause analysis tools, including:

- Pareto Chart

- The 5 Whys

- Fishbone Diagram

- Scatter Diagram

- Failure Mode and Effects Analysis (FMEA)

1.

Pareto Chart

A Pareto chart is a histogram or bar

chart combined with a line graph that groups the frequency or

cost of different

problems to show their relative significance. The bars show frequency in

descending order,

while the line shows cumulative percentage or total as you

move from left to right.

The Pareto chart example above is a

report from layered process audit software that groups

together the top

seven categories of failed audit questions for a given

facility. Layered process audits (LPAs) allow you to

check high-risk processes

daily to verify conformance to standards. LPAs identify process variations that

cause defects, making Pareto charts a powerful reporting tool for analyzing LPA

findings.

Pareto charts are one of the seven

basic tools of quality described by quality pioneer Joseph Juran.

Pareto charts

are based on Pareto’s law, also called the 80/20 rule, which says that 20% of inputs

drive

80% of results.

2.

5 Whys

The 5 Whys is a method that uses a

series of questions to drill down into successive layers of a problem.

The

basic idea is that each time you ask why, the answer becomes the basis of the

next why.

It’s a simple tool useful for problems where you don’t need advanced

statistics, so you don’t necessarily

want to use it for complex problems.

One application of this technique is

to more deeply analyze the results of a Pareto analysis.

Here’s an example of

how to use the 5 Whys:

Problem: Final assembly time exceeds

target

- Why is downtime in final assembly higher than our goal? According to the Pareto chart, the biggest factor is operators needing to constantly adjust Machine A

- Why do operators need to constantly adjust Machine A? Because it keeps having alignment problems

- Why does Machine A keep having alignment problems? Because the seals are worn

- Why are Machine A’s seals worn? Because they aren’t being replaced as part of our preventive maintenance program

- Why aren’t they being replaced as part of our preventive maintenance program? Because seal replacement wasn’t captured in the needs assessment

Of course, it may take asking why

more than five times to solve the problem—

the point is to peel away

surface-level issues to get to the root cause.

3.

Fishbone Diagram

A fishbone diagram sorts possible

causes into various categories that branch off from the original problem.

Also

called a cause-and-effect or Ishakawa diagram, a fishbone diagram may have

multiple sub-causes

branching off of each identified category.

4.

Scatter Plot Diagram

A scatter plot or scatter diagram

uses pairs of data points to help uncover relationships between variables.

A

scatter plot is a quantitative method for determining whether two variables are

correlated, such as

testing potential causes identified in your fishbone

diagram.

Making a scatter diagram is as

simple as plotting your independent variable (or suspected cause)

on the

x-axis, and your dependent variable (the effect) on the y-axis. If the pattern

shows a clear line

or curve, you know the variables are correlated and you can

proceed to regression or correlation analysis.

5.

Failure Mode and Effects Analysis (FMEA)

Failure mode and effects analysis

(FMEA) is a method used during product or process design to

explore potential

defects or failures. An FMEA chart outlines:

- Potential failures, consequences and causes

- Current controls to prevent each type of failure

(RPN) for

determining further action

Lean Six Sigma

Lean Six Sigma is a process that aims to systematically eliminate waste and reduce variation.

SCADA System

Supervisory control and data acquisition (SCADA) systems are a computer system used to monitor

and control plant processes.

SCADA

Supervisory control and data acquisition (SCADA) is a system of software and hardware elementsthat allows industrial organizations to:

- Control industrial processes locally or at remote locations

- Monitor, gather, and process real-time data

- Directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software

- Record events into a log file

process data for smarter decisions,

and communicate system issues to help mitigate downtime.

The basic SCADA architecture begins with programmable logic controllers (PLCs) or remote terminal

The basic SCADA architecture begins with programmable logic controllers (PLCs) or remote terminal

units (RTUs). PLCs and RTUs are

microcomputers that communicate with an array of objects such as

factory

machines, HMIs, sensors, and end devices, and then route the

information from those objects

to computers with SCADA software. The

SCADA software processes, distributes, and displays the

data, helping

operators and other employees analyze the data and make important

decisions.

For example, the SCADA system quickly notifies an operator that a batch of product is showing

For example, the SCADA system quickly notifies an operator that a batch of product is showing

a high incidence of errors. The operator

pauses the operation and views the SCADA system data via

an HMI to

determine the cause of the issue. The operator reviews the data and

discovers

that Machine 4 was malfunctioning. The SCADA system’s ability

to notify the operator of an issue

helps him to resolve it and prevent

further loss of product.

Planned Maintenance Optimization

Planned

Maintenance Optimization (PMO) is a method of improving maintenance

strategies based

on existing preventive maintenance (PM) routines and

available failure history.

What is planned maintenance optimization?

Planned Maintenance Optimization (PMO) is a method of improving maintenance strategies basedon existing preventive maintenance (PM) routines and

available failure history.

Overview

While most companies have identified the need for a preventive maintenance (PM) program,the effective execution of such maintenance activities can be

challenging given the everyday demands

of a facility. Unseen

circumstances that require urgent attention can easily derail planned

activities

and can potentially disrupt a smoothly running plant.

While alternatives such as reliability centered maintenance (RCM) addresses some of the factors

While alternatives such as reliability centered maintenance (RCM) addresses some of the factors

that make PM a cost- and labor-intensive

process, coming up with a robust RCM strategy may

take long periods of

time.

PMO provides a method through which maintenance activities are carried out more efficiently.

PMO provides a method through which maintenance activities are carried out more efficiently.

By performing PMO, a new maintenance

strategy is derived from existing PM tasks.

Given the existing tasks,

modifications on the schedule and frequency of the routines are done

based

on the failure history of the equipment. With a relatively shorter

time to develop, the resulting

strategy can be similar to performing

RCM.

The three phases of PMO

The PMO process can be summarized in three phases:Data collection

Any attempt at optimization starts with good, reliable data. Data on equipment performance,particularly on failure history over time, must

be collected. A minimum time period must be set to

ensure that enough

insight is obtained from the data. Tools such as a CMMS program can make

this process easier and more accurate.

Data analysis, review, and recommendations

The collected data must be analyzed to identify which equipment is the most critical. Some points toconsider are criticality to the plant’s

operations, cost to repair, MTBF, and MTR.

The information gathered from analyzing the data must then be reviewed against existing PM routines.

The information gathered from analyzing the data must then be reviewed against existing PM routines.

Some key points to review are: 1) whether

the PM routines are scheduled correctly to align with the

MTBF and MTR

data points, and 2) whether failure points are within acceptable

tolerances set by

original equipment manufacturer (OEM) specifications

or industry standards. Any substantial deviations

from such checks can

be a source of improvement from a maintenance standpoint.

Based on the review, recommendations on modifications for the PM tasks should be made. Schedules

Based on the review, recommendations on modifications for the PM tasks should be made. Schedules

and frequencies of activities need to be optimized to

meet MTBF and MTR constraints. Any missing

maintenance activities, as

well as redundancies in tasks, need to be addressed accordingly.

Agreement and execution

Agreed action items must be delegated properly. Identified task owners should be accountable for anyrequired action and monitored for progress. Note

that the PMO process is a continuous effort and

reviews should be done

habitually.

Benefits of applying PMO

Regular maintenance activities are clearly a key part in ensuring a plant’s reliability. But PMO furtherincreases the benefits of maintenance activities by showing

substantial reductions in costs.

In the laboratory and life sciences industry, a PMO program is estimated to reduce overall maintenance

In the laboratory and life sciences industry, a PMO program is estimated to reduce overall maintenance

costs by around 25%.

Payback periods of investing in a PMO strategy are estimated at around

12 to 24 months, just considering the measured savings from maintenance

costs.

Aside from the improvements in uptime and reliability that come with a robust maintenance strategy,

Aside from the improvements in uptime and reliability that come with a robust maintenance strategy,

PMO methods enable company

resources to be spent more wisely without sacrificing the quality

of

execution of maintenance tasks.

Conclusion

Maintenance activities, particularly PM activities, are already proven concepts that increase theoverall performance of a plant. With continuous practice,

PMO is a tool that can help execute

PM activities more efficiently and

effectively.

Standards

ISO 55000

To

comply with ISO 55000 you must have an asset management system.

The

goal of an asset management system is to establish the policies,

objectives, and processes needed

to achieve an organization’s goals.

ISO 55001

The

components of an asset management system that are listed out in ISO

55000 are elaborated on

in ISO 55001. These components include

organizational context, leadership, planning, support,

operation,

performance evaluation, and improvement.

ISO 55002

ISO 55002 provides the most significant details needed to achieve compliance with ISO 55000.

SAE JA1011

SAE

JA1011 was initially developed by the commercial aviation industry to

improve the safety

and reliability of their equipment.

Because of this,

it’s known as a Reliability-Centered Maintenance (RCM) process.

Regulations

FDA Maintenance Regulations

FDA

inspections are typically conducted by reviewing systems which

correspond to the Subparts

that are applicable to the type of

product/facility being audited. In the case of maintenance,

Subparts for

Buildings and Facilities and Equipment are of the main concern.

OSHA Maintenance Regulations

Maintenance

workers are among the many workers that are exposed to workplace

hazards on a daily

basis. OSHA aims to protect them by providing access

to information for vulnerable workers in

high-risk jobs.

IRS Maintenance Regulations

There

are specific deductible and capital improvement costs that are directly

related to maintenance

operations and the IRS provides information

about how it allows businesses to recover those costs.

Documents

Equipment Maintenance Log

An equipment maintenance log is a document that records activities that have been performed on an asset.

Operation and Maintenance Manual

An

operation and maintenance manual is a comprehensive document that

provides all the details

necessary about a physical plant as well as

individual pieces of equipment to help the

maintenance staff keep

everything running smoothly.