SIX SIGMA - LEAN SIX SIGMA - ADVANTAGES FOR FOR TEXTILE INDUSTRY

Different definitions have been proposed for Six Sigma, but they all share some common threads:

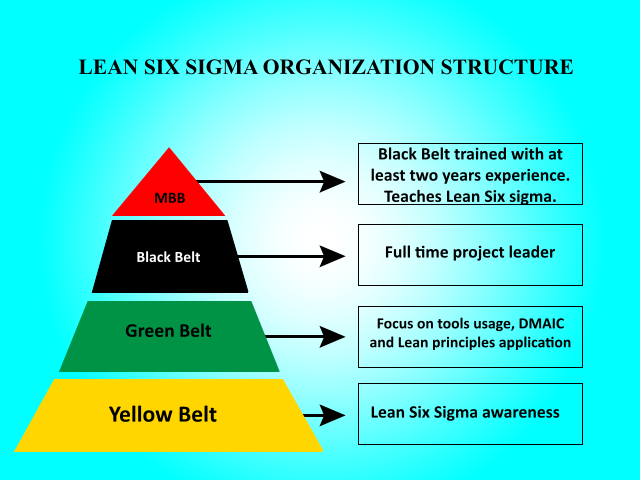

- Use of teams that are assigned well-defined projects that have direct impact on the organization's bottom line.

- Training in "statistical thinking" at all levels and providing

key people with extensive training in advanced statistics and project

management. These key people are designated “Black Belts.” Review the different Six Sigma Belts ,levels and roles.

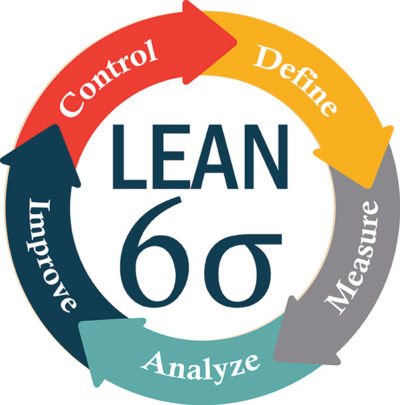

- Emphasis on the DMAIC approach to problem solving: define, measure, analyze, improve, and control.

- A management environment that supports these initiatives as a business strategy.

Differing opinions on the definition of Six Sigma:

Philosophy— The philosophical perspective views all work as processes that can be defined, measured, analyzed, improved and controlled. Processes require inputs (x) and produce outputs (y). If you control the inputs, you will control the outputs. This is generally expressed as y = f(x).Set of tools— The Six Sigma expert uses qualitative and quantitative techniques to drive process improvement. A few such tools include statistical process contro (SPA), control charts,failure mode and effects analysis, and process mapping. Six Sigma professionals do not totally agree as to exactly which tools constitute the set.

Methodology— This view of Six Sigma recognizes the underlying and rigorous approach known as DMAIC ( define,measure,analyze,improve and control) . DMAIC defines the steps a Six Sigma practitioner is expected to follow, starting with identifying the problem and ending with the implementation of long-lasting solutions. While DMAIC is not the only Six Sigma methodology in use, it is certainly the most widely adopted and recognized.

Metrics – In simple terms, Six Sigma quality performance means 3.4 defects per million opportunities (accounting for a 1.5-sigma shift in the mean).

Some argue that many of the tools Six Sigma uses are not new. However, while Six Sigma uses conventional methods, its application is anything but conventional. Instead it stresses the importance of searching for a new way of thinking and doing. In fact, Six Sigma defines a clear road map to achieve Total Quality:

- Leadership Commitment: Top management not only initiates Six Sigma deployment, it also plays an active role in the whole deployment cycle. Six Sigma starts by providing senior leadership with training in the principles and tools it needs to direct the development of a management infrastructure to support Six Sigma. This involves reducing the levels of organizational hierarchy and removing procedural barriers to experimentation and change.

- Customer Focus: Systems are developed for establishing close communications with “external customers” (direct customers, end-users, suppliers, regulatory bodies, etc), and with internal customers (employees). From upstream suppliers to ultimate end-users, Six Sigma eliminates the opportunities for defects.

- Strategic Deployment: Six Sigma targets a small number of high-financial leveraged items. It focuses the company’s resources: right support, right people, right project, and right tools, on identifying and improving performance metrics that relate to bottom-line success.

- Integrated Infrastructure: The Leadership Team defines and reviews project progress. The Champion acts as a political leader and removes the barriers for the project team. The Master Black Belt acts as a technical coach and provides in-depth knowledge of quality tools. The Black Belt controls the project while the Green Belt supports the Black Belt - together they form the Six Sigma Project Teams. In addition, the incentive and recognition systems motivate the project teams to achieve the business goals.

- Disciplined Framework: Six Sigma projects are Implemented using the Measure, Analyze, Improve and Control disciplined road map. This MAIC discipline sets up a clear protocol to facilitate internal communication. In addition, from a business perspective, Six Sigma is also a framework for continuous business improvement.

- Education and Training: Six Sigma believes that true commitment is driven by true understanding. As a fact-based methodology, it intensively utilizes quality and statistical tools to transform a practical problem to a practical solution. Thus, a top-to-bottom training is conducted in Six Sigma philosophy and system improvement techniques for all levels.

Lean manufacturing

(lean production)

Lean manufacturing is a methodology that focuses on

minimizing waste within manufacturing systems while simultaneously maximizing

productivity.

Also known as lean production, or just lean, the integrated

sociotechnical approach is based on the Toyota Production System and is still

used by that company, as well as myriad others, including Caterpillar Inc. and

Nike.

Lean manufacturing is based on a number of specific

principles, such as Kaizen, or continuous improvement.

Five principles of lean manufacturing

A widely referenced book, Lean Thinking: Banish Waste and

Create Wealth in Your Corporation, which was published in 1996, laid out five

principles of lean, which many in the field reference as core principles. They

are value, the value stream, flow, pull and perfection. These are now used as

the basis for lean implementation.

1. Identify value

from the customer's perspective. Value is created by the producer, but

it is defined by the customer. In other words, companies need to understand the

value the customer places on their products and services, which, in turn, can help

them determine how much money the customer is willing to pay.

The company must strive to eliminate waste and cost from its

business processes so that the customer's optimal price can be achieved at the

highest profit to the company.

2. Map the value

stream. This principle involves recording and analyzing the flow of

information or materials required to produce a specific product or service with

the intent of identifying waste and methods of improvement. The value stream

encompasses the product's entire lifecycle, from raw materials through to

disposal.

Companies must examine each stage of the cycle for waste --

or muda in Japanese. Anything that does not add value must be eliminated. Lean

thinking recommends supply chain alignment as part of this effort.

3. Create flow.

Eliminate functional barriers and identify ways to improve lead time to ensure

the processes are smooth from the time an order is received through to

delivery. Flow is critical to the elimination of waste. Lean manufacturing

relies on preventing interruptions in the production process and enabling a

harmonized and integrated set of processes in which activities move in a

constant stream.

4. Establish a

pull system. This means you only start new work when there is demand

for it. Lean manufacturing uses a pull system instead of a push system.

With a push system, used by manufacturing resource planning

(MRP) systems, inventory needs are determined in advance and the product is

manufactured to meet that forecast. However, forecasts are typically

inaccurate, which can result in swings between too much inventory and not

enough, as well as subsequent disrupted schedules and poor customer service.

In contrast to MRP, lean manufacturing is based on a pull

system in which nothing is bought or made until there is demand. Pull relies on

flexibility and communication.

5. Pursue

perfection with continual process improvement, or kaizen. Lean

manufacturing rests on the concept of continually striving for perfection,

which entails targeting the root causes of quality issues and ferreting out and

eliminating waste across the value stream.

The eight wastes of

lean production

1.

unnecessary transportation;

2.

excess inventory;

3.

unnecessary motion of people, equipment or

machinery;

4.

waiting, whether it is people waiting or idle

equipment;

5.

over-production of a product;

6.

over-processing or putting more time into a

product than a customer needs, such as designs that require high-tech machinery

for unnecessary features; and

7.

defects, which require effort and cost for

corrections.

8.

Waste of unused talent and ingenuity.

Lean manufacturing

tools and concepts

Lean manufacturing requires a relentless pursuit of reducing

waste. Waste is anything that customers do not believe adds value and for which

they are not willing to pay. This requires continuous improvement, which lies

at the heart of lean manufacturing.

Other important concepts and processes lean relies on

include:

Heijunka: production leveling or smoothing that

seeks to produce a continuous flow of production, releasing work to the plant

at the required rate and avoiding interruptions.

Kanban: a signal

-- either physical, such as tag or empty bin, or electronically sent through a

system -- used to streamline processes and create just-in-time delivery.

Jidoka: A method

of providing machines and humans with the ability to detect an abnormality and

stop work until it can be corrected. Jidoka is about built in quality and

encompasses ideas such as Autonomation

which is giving machines the “human touch” so that they can stop when things

are incorrect, also Poka Yoke or mistake proofing to prevent defects being

produced, accepted or passed on. It also encompasses the philosophy of stopping

the production line when defects are discovered,

Andon: A visual

aid, such as a flashing light, that alerts workers to a problem.

Poka-yoke: A

mechanism that safeguards against human error, such as an indicator light that

turns on if a necessary step was missed, a sign given when a bolt was tightened

the correct number of times or a system that blocks a next step until all the

previous steps are completed.

5S: A set of

practices for organizing workspaces to create efficient, effective and safe

areas for workers and which prevent wasted effort and time. 5S emphasizes

organization and cleanliness.

Total Productive

Maintenance is the machinery equivalent of Total Quality Management (TQM)

and involves everyone in the organization in focusing on eliminating the six

big losses through the use of a performance measure known as OEE. TPM builds on

Preventive maintenance and predictive maintenance programs and involves the

operators through autonomous maintenance.

Kaizen is all

about continuously improving every process in your business. This can be done

through ongoing continual improvement or through a dedicated Kaizen Blitz

designed to make a rapid improvement to a specific area of your business.

Process mapping

your value stream using ideas and techniques such as Value Stream Mapping (VSM)

or simple Flow charting or spaghetti diagrams

are very powerful ways to identify and highlight the wasteful steps in

your processes. This allows you to create future state maps and create action

plans to simplify your work and drive improvements.

Cycle time: How

long it takes to produce a part or complete a process.

Takt time

is the maximum amount of time in which a product needs to be produced

in order to satisfy customer demand. The term comes from the German word

"takt," which means "pulse." Set by customer demand, takt creates the

pulse or rhythm across all processes in a business to ensure continuous

flow and utilization of capacities (e.g., man and machine).

Single Minute Exchange of Dies, which is a process of reducing changeover (setup) time by classifying elements as internal or external to a machine’s operating time and then converting the internal elements so they can be done externally (while the machine continues to operate).

What is lean Six Sigma?

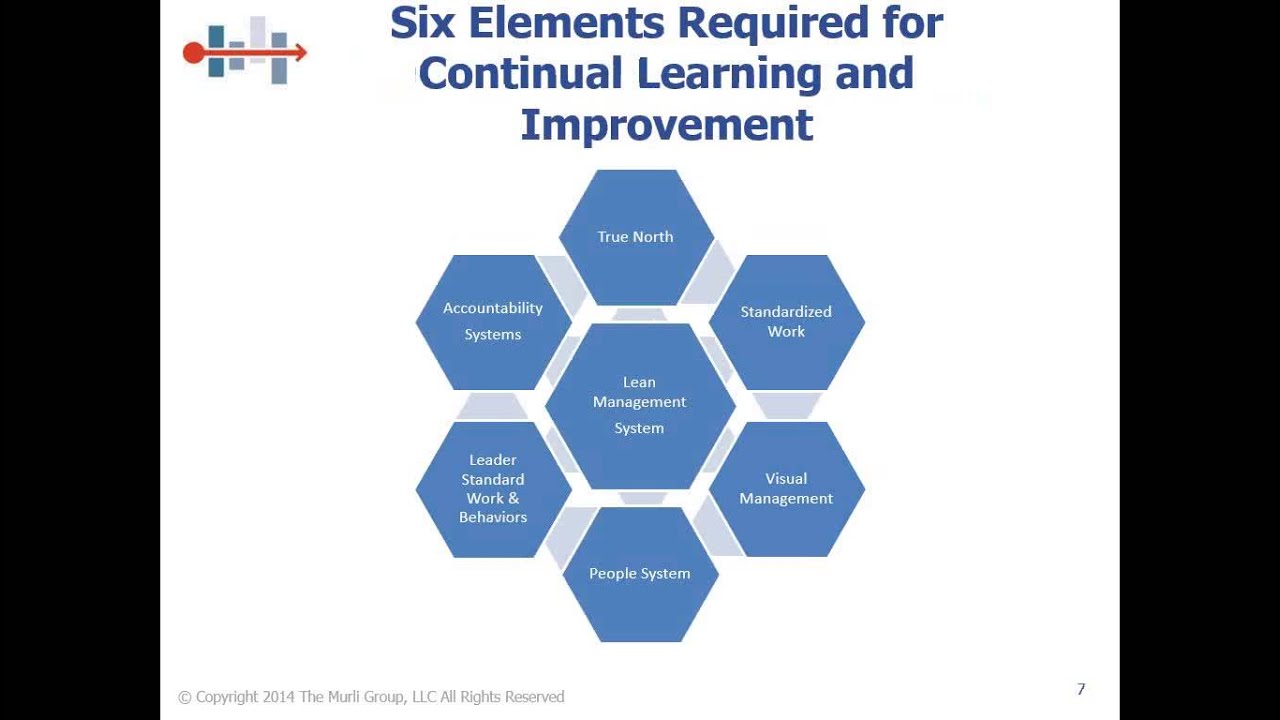

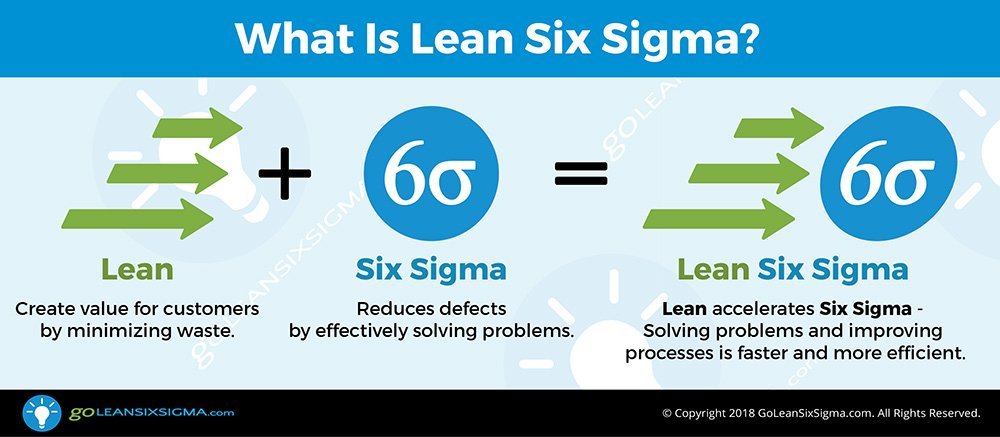

Lean Six Sigma is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection. It drives customer satisfaction and bottom-line results by reducing variation, waste, and cycle time, while promoting the use of work standardization and flow, thereby creating a competitive advantage. It applies anywhere variation and waste exist, and every employee should be involved.The demarcation between Six Sigma and lean has blurred. We are hearing about terms such as “lean Six Sigma” with greater frequency because process improvement requires aspects of both approaches to attain positive results.

Six Sigma focuses on reducing process variation and enhancing process control, whereas lean drives out waste (non-value-added) and promotes work standardization and flow. Six Sigma practitioners should be well versed in both.

Integrating lean and Six Sigma

Both lean and Six Sigma seek to eliminate waste. However,

the two use different approaches because they see the root cause of waste

differently.

In the simplest terms, whereas lean holds that waste is

caused by additional steps, processes and features that a customer doesn't

believe adds value and won't pay for, Six Sigma holds that waste results from

process variation. Still, the two approaches are complementary and have been

combined as Lean Six Sigma.

Lean Six Sigma is a combination of two powerful process

improvement methods: Lean and Six Sigma.

Lean Six Sigma decreases your organization’s costs by:

Removing “Waste” from a process. Waste is any activity

within a process that isn’t required to manufacture a product or provide a

service that is up to specification.

Solving problems caused by a process. Problems are defects

in a product or service that cost your organization money

Lean is popular for its methodical approach to streamlining

both manufacturing and service processes by eliminating waste while continuing

to deliver value to customers.

Six Sigma is simply a method of efficiently solving a

problem. Using Six Sigma reduces the amount of defective products manufactured

or services provided, resulting in increased revenue and greater customer

satisfaction.

Lean and Six Sigma have the same general purpose of providing the customer with the best possible quality, cost, delivery, and a newer attribute, nimbleness. There is a great deal of overlap, and disciples of both disagree as to which techniques belong where.

The two initiatives approach their common purpose from slightly different angles:

• Lean focuses on waste reduction, whereas Six Sigma emphasizes variation reduction

• Lean achieves its goals by using less technical tools such as kaizen, workplace organization, and visual controls, whereas Six Sigma tends to use statistical data analysis , design of experiments, and hypothesis tests.

The most successful users of implementations have begun with the lean approach making the workplace as efficient and effective as possible, reducing waste, and using value stream maps to improve understanding and throughput.

When process problems remain, the more technical Six Sigma statistical tools may be applied. One thing they have in common is that both require strong management support to make them the standard way of doing business.

Some organizations have responded to this dichotomy of approaches by forming a lean-Six Sigma problem-solving team with specialists in the various aspects of each discipline but with each member cognizant of others’ fields. Task forces from this team are formed and reshaped depending on the problem at hand.

Six Sigma Process Models:

Six sigma facilitated proactive approach through rigorous measurement. Some six sigma models are given below. DMAIC is used to improve the existing process and DMADV is used to employ the new products.

1. DMAIC (Define, Measure, Analyze, Improve, Control)

• Define - Define the project goals and customer (internal and external) deliverables.

• Measure - Measure the process to determine current performance.

• Analyse - Analyse and determine the root causes of the defects.

• Improve - Improve the process by eliminate defects.

• Control - Control future process performance.

2. DMADV (Define, Measure, Analyze, Design, Verify)

• Define - Define the project goals and customer (internal and external) deliverables.

• Measure - Measure and determine customer needs and specifications.

• Analyze - Analyze the process options to meet the customer needs.

• Design - Design (detailed) the process to meet the customer needs.

• Verify - Verify the design performance and ability to meet customer needs.

Critical Success Factors of Six sigma

The system needed to achieve Six Sigma creates a culture characterised by:

• Customer centricity

• Financial results

• Management engagement

• Resource commitment

• Execution infrastructure

Six Sigma - Organisational Structure

Seven Steps for Six Sigma

when a company intends to introduce Six Sigma for its new management strategy, the author's would like to recommend the following seven-step procedures:

1. Top-level management commitment for Six Sigma is first and foremost. Then organise a Six Sigma team and set up the long-term Six Sigma vision for the company.

2. Start Six Sigma education for Champions first. Then start the education for White belt- WBs, Green Belt-GBs, Black Belt-BBs and MBBs in sequence.

3. Choose the area in which Six Sigma will be first introduced.

4. Deploy Critical to Quality - CTQs for all processes concerned. The most important is the company’s deployment of big CTQy from the standpoint of customer satisfaction. Appoint BBs as full-time project leaders and ask them to solve some important CTQ problems.

5. Strengthen the infrastructure for Six Sigma, including measurement systems, statistical process control (SPC), knowledge management (KM) and database management system (DBMS).

6. Designate a Six Sigma day each month, and have the progress of Six Sigma reviewed by top-level management.

7. Evaluate the company’s Six Sigma performance from the customers’ viewpoint, benchmark the best company in the world, and revise the Six Sigma roadmap if necessary. Go to step 1 for further improvement.

Possible Areas in Textile Industry for Six sigma application:

Textile/Fashion Houses/Export Houses or Buying Houses have potential of applying Six Sigma in following improvement projects:

1. Reducing rejections in shipments.

2. Improving first sample approval percentages while working with buyer.

3. Improving supplier evaluation processes.

4. Improving AQL performance in shipments.

5. Improving merchandiser performance.

6. Reducing non conformances in audits by buyer.

7. Improving processes at the source (including fabric purchase and inspection, stitching, embroidery, packing and shipping) to reduce rejections at later stages.

8. Eliminating manufacturing errors/defect.

Convincing apparel executives to accept the process, other than as a selling tool, has been a difficult task. About the only agreement reached is that every garment cannot be manufactured to the perfect specification. However, the typical manufacturing plant is producing apparel at about a 3 sigma level with 2.5 to 4% defects. That is 4 defects per 100 not the 3.4 defects per 1,000,000 produced by a Six Sigma manufacturer. The gap is wide enough that significant improvement can be made in any such plant. Two financial facts are important to note.

Historical studies have shown overall savings in the $10,000 to $20,000 range for an improvement of just one Sigma. Apparel managers are generally astounded by the “True Cost of Quality” in their manufacturing facility. Typically, these costs are hidden in overhead but include inspection and marking, sorting, transport, reinspection, supervisor time, downstream operator repair, cleaning, and irregulars. Therefore, any improvement in quality has a triple effect of reducing indirect labour, lowering total fabric cost, and improving customer satisfaction.

DuPont uses the programme for its productivity and quality improvement strategies. It considers Six Sigma a business-management process that concentrates on eliminating defects from work processes. The company now has more than 4,000 completed or in-process Six Sigma projects. Other textile companies, such as Burlington Industries, Collins and Aikman, and PGI have also started Six Sigma initiatives.

Seven basic SQC tools used in Six Sigma process:

1. Cause and effect diagram

2. Check sheet

3. Control chart

4. Histogram

5. Pareto chart

6. Scatter diagram

7. Stratification

Six Sigma has provided lot of benefits in Quality Checking Systems to eradicate pilferage and raw defects. The Process Sigma level has also improved for both the manufacturing and operations. In terms of percentage, there has been an exponential growth in woven products.

The textile industry is important in the business sector of India and it has to face cut throat competition in market. The Indian textile industry is rapidly repositioning itself in the fashion and textile world. Indian textile designers are planning to diverge hierarchy as per global scenario hence there is need to adopt improvised reputation driven technologies to not only manage supplies, but also control output to enhance manpower productivity.

The unemployment ratio is increasing day by day in textile world. Textile Industry is the second largest Industry in the country which supports lot of employment whether directly or indirectly.

Below outlined are top 10 benefits of Six Sigma in Textile industry

- Utilization of resources, and increasing employment by its cause and effect relation.

- It improves product output in manufacturing and production

- Reducing over time problems for staff and eliminating child labour

- Eradicating environmental issues which are caused by emission of negative substances produced by textile industries

- Its ensures health safety of employees

- Six Sigma shows how to align the organization through customer-focused measures of performance

- The efficiency of Six Sigma gains benefits to get more production within limited available resources

- Six Sigma role has been quite significant in developing India’s GDP through textile industries

- It assists is fixing and creating solutions to enhance export of textile overseas

Six Sigma VS. Total

Quality Management (TQM)

In some aspects of quality improvement, TQM and Six Sigma

share the same philosophy of how to assist organizations to accomplish Total

Quality. They both emphasize the importance of top-management support and

leadership. Both approaches make it clear that continuous quality improvement is

critical to long-term business success. However, why has the popularity of TQM

waned while Six Sigma's popularity continues to grow in the past decade?

T. Pyzdek (Why Six Sigma is Not TQM, 2001) stated that the primary difference is management. Unlike TQM, Six Sigma was not developed by technicians who only dabbled in management and therefore produced only broad guidelines for management to follow. The Six Sigma way of implementation was created by some of America's most gifted CEOs - people like Motorola's Bob Galvin, Allied Signal's Larry Bossidy, and GE's Jack Welch. These people had a single goal in mind: making their businesses as successful as possible. Once they were convinced that tools and techniques of Six Sigma could help them do this, they developed a framework to make it happen.

The differences between TQM and Six Sigma are summarized in Table

| TQM | Six Sigma |

| A functional specialty within the organization. | An infrastructure of dedicated change agents. Focuses on cross-functional value delivery streams rather than functional division of labour. |

| Focuses on quality. | Focuses on strategic goals and applies them to cost, schedule and other key business metrics. |

| Motivated by quality idealism. | Driven by tangible benefit far a major stockholder group (customers, shareholders, and employees). |

| Loosely monitors progress toward goals. | Ensures that the investment produces the expected return. |

| People are engaged in routine duties (Planning, improvement, and control). | “Slack” resources are created to change key business processes and the organization itself. |

| Emphasizes problem solving. | Emphasizes breakthrough rates of improvement. |

| Focuses on standard performance, e.g. ISO 9000. | Focuses on world class performance, e.g., 3.4 PPM error rate. |

| Quality is a permanent, full-time job. Career path is in the quality profession. | Six Sigma job is temporary. Six Sigma is a stepping-stone; career path leads elsewhere. |

| Provides a vast set of tools and techniques with no clear framework for using them effectively. | Provides a selected subset of tools and techniques and a clearly defined framework for using them to achieve results (DMAIC). |

| Goals are developed by quality department based on quality criteria and the assumption that what is good for quality is good for the organization. | Goals flow down from customers and senior leadership's strategic objectives. Goals and metrics are reviewed at the enterprise level to assure that local sub-optimization does not occur. |

| Developed by technical personnel. | Developed by CEOs. |

| Focuses on long-term results. Expected payoff is not well-defined. | Six Sigma looks for a mix of short-term and long-term results, as dictated by business demands. |

Conclusion

Six Sigma is a new strategic paradigm of management innovation for company survival in this 21st century which implies three things such as statistical measurement, management strategy and quality culture. Six Sigma with its 4S (systematic, scientific, statistical and smarter) approaches provides flexibility in managing a business unit. Textile industry being a field dealing with lot of variations and defects in each process is the exact place for six sigma application. The speedy implementation of the right method will make a significant and successful difference in many of the companies’ future.

https://www.udemy.com/free-lean-six-sigma-primer/learn/v4/t/lecture/4318856?start=0

Ref : ITJ July 2010

ASQ .org

henry harvin education

15 comments:

Everyone wants to get unique place in the IT industry’s for that you need to upgrade your skills, your blog helps me improvise my skill set to get good career, keep sharing your thoughts with us.

Business Management Software

Nice Article! its helps me alot. actually i was founding some unique information regarding six sigma black belt certification and your article helps me.

anyway i have some information about it you may checked- https://www.henryharvin.com/leansix-sigma-black-belt-certification

Great. Useful for Real Technocrats.

Digital Marketing Training in KPHB with 100% Internships & Job Assistance

very nice article,this is extremely great and it is very useful for us.

Adamjee Enterprise

SIX SIGMA BLACK BELT CERTIFICATION

We offer the most developed Certified Six Sigma Black Belt Course according to the educational program framework of ASQ - Body of Knowledge and authorize by top global Lean and Six Sigma authorization bodies click on this link six sigma black belt

Dirty, cluttered factories, manufacturing plants, workshops and production facilities are a thing of the past. These days, with a keen focus on lean manufacturing, waste reduction and efficiency, manufacturers and engineering firms place huge importance on keeping their workstations and production lines spotless. Research also shows that production facilities which maintain high levels of cleanliness are more productive and have fewer running costs.

Best Industrial and Factory Cleaning Services in South Wales

SIX SIGMA GREEN BELT CERTIFICATION

We offer the most advanced “Certified Six Sigma Green Belt Course” SIX SIGMA GREEN BELT CERTIFICATION

The Lean Six Sigma certification provided by MindCypress will help you to gain proficiency in both the Green and black belts. With online training and virtual classes, the up-to-date curriculum of these courses has helped me to learn about the DMAIC procedure that is aligned with the main green belt accreditation of the Council of Six Sigma certification.

Much informative blog!!! Do share more blogs like this.

Shipment management software helps in planning & executing the physical movement of goods. It can be used by all members of the supply chain from manufacturers to distributors.

Lean six sigma green belt certification course benefits a good understanding of improvement and analytical tools to be used in order to have a big impact on the company. Mindcypress's course provides you with a detailed understanding of the Lean Six Sigma approach to drive competitive advantage through the effective and efficient application of data-driven process improvement in the organization. It is much more than just training in tools, it provides deep insights into the underlying concepts and the framework of Lean Six Sigma. You also have in-depth knowledge of the connected fields of statistics and process improvement, which can be helpful when solving complex process problems.

lean manufacturing online courses offer flexible, self-paced training on eliminating waste, improving workflow, and optimizing production. Participants learn key Lean tools like 5S, Kaizen, and Value Stream Mapping, helping organizations boost efficiency, reduce costs, and improve quality.

Very neat blog article. Really looking forward to reading more. Want more?

Best Puppet Training from South Africa

Chef Online Training from Chennai

Maven Training from UK

Ansible Training Institute In Hyderabad

Jenkins Training from Pune

Terraform Online Coaching In Australia

Github Online Classes

Thanks so much for the blog article. Really looking forward to reading more. Want more?

AWS Redshift Training Course Online

Best OSB Online Certification Training India

AdminStudio, InstallShield Online Training

Ab Initio Online Live Classes

SAP PP Production Planning Self paced Training Videos

Oracle Applications Technical Online Training from Hyderabad

Data Science Online Training from India

SAP ABAP On Hana Training

SAP BODS Realtime Online Support In India

I value the article post. Really thank you! Really Great.

JAVA Spring Training from Hyderabad

Groovy Real-time Online Support In India

Best SAP BOBJ Training

SAP Enterprise Portal Online Training Course

SAP BPC 11 Online Training from India

SAP IBP Certification Online Training from Hyderabad

Best SAP Environment, Health, and Safety Online Certification Training India

SAP CPQ Online Training Institute In Hyderabad

SAP C4C Technical Self-Paced Training videos

Best SAP CRM Techincal Online Training

Post a Comment