DIFFERENT TYPES OF YARN COMPACTING SYSTEMS

COMPACT SPINNING

In conventional ring spinning, fibres in the selvedge of strand emerging from front roller nip do not get fully integrated into the yarn because of the restriction to twist flow by the spinning triangle. These fibres show up partly as protruding hairs or as wild fibres.

The spinning triangle exists because of higher width of the strand as compared to final yarn diameter. Further the fibres are tensioned to varying extent depending upon their position in the spinning triangle. As a result full realization of fibre strength is not achieved in the yarn.

The hairiness gives a rough feel to the yarn. Variation in hairiness is a source of weft bars and warp way streaks in the fabric. Long protruding hairs from the yarn contribute to multiple breaks in weaving and fabric faults like stitches and floats.

The delivery cylinder of the drafting system has been

replaced by a perforated drum(1). The directly driven perforated

drum is wear-free surface and is also free of fibre drag. Each drum has an

exchangeable stationary suction insert, with a specially shaped slot, which

is connected to the machine's suction system(2) and generates

airflow from outside into the interior of the drum. The fibres supplied by

the main draft of the drafting system are held firmly to the surface of the

perforated drum by the air current and move at the circumferential speed of

the perforated drum. The fibre web is compacted in the fibre compacting

zone. The air current generated by the vacuum in the perforated drum enables

the fibres to be compacted efficiently following the main draft. This

compacting process is supported by a specially designed and patented air

guide element(6).

The delivery cylinder of the drafting system has been

replaced by a perforated drum(1). The directly driven perforated

drum is wear-free surface and is also free of fibre drag. Each drum has an

exchangeable stationary suction insert, with a specially shaped slot, which

is connected to the machine's suction system(2) and generates

airflow from outside into the interior of the drum. The fibres supplied by

the main draft of the drafting system are held firmly to the surface of the

perforated drum by the air current and move at the circumferential speed of

the perforated drum. The fibre web is compacted in the fibre compacting

zone. The air current generated by the vacuum in the perforated drum enables

the fibres to be compacted efficiently following the main draft. This

compacting process is supported by a specially designed and patented air

guide element(6).

The special feature of "Air Guide element" is to enhance the compacting efficiency in the compacting zone (Figure 5). A second top roller located after the compacting zone, the so-called nip roll(5), clamps the spinning triangle. As a result of the compacting process, width 'b' (Figure 3) of the fibre bundle entering the twist insertion zone is considerably smaller than width 'B' of the fibre bundle emerging from the drafting mechanism, so that the size of the spinning triangle is substantially reduced. Subsequent twist insertion is similar to that in the ring spinning process. Optimum interaction of the compacting elements ensures complete compacting of all fibres. This results in the typical properties of yarn as called by Rieter "COM4® yarn".

The bottom rollers(1), support the front roller(2) and delivery roller(3). The condensing zone extends from clamping line A to B. The very precise magnetic compactor(4) is pressed by permanent magnets without clearance against cylinder(1). It forms, together with the bottom roller, an overall enclosed compression chamber whose bottom contour, the generated roller surface of the cylinder, moves synchronously with the strand of fibres and transports this safely through the compactor. The manufacturer offers two types of the compacting system(17):

It has already been proved and established by many researchers and industrial people that the compact yarns have improved quality in comparison to conventional yarns and subsequently results in substantial improvement in the downstream processing. There are many methods offered by the machine manufacturers to choose for making compact yarn. Some of these methods, especially based on aerodynamic compacting, are already proven and running successfully in the mills. Still there is scope for spinning mills to establish the workability of other compacting methods offered by the manufacturers.

Courtesy : ITJ August 2009

ITJ August 2007

COMPACT SPINNING

In conventional ring spinning, fibres in the selvedge of strand emerging from front roller nip do not get fully integrated into the yarn because of the restriction to twist flow by the spinning triangle. These fibres show up partly as protruding hairs or as wild fibres.

The spinning triangle exists because of higher width of the strand as compared to final yarn diameter. Further the fibres are tensioned to varying extent depending upon their position in the spinning triangle. As a result full realization of fibre strength is not achieved in the yarn.

The hairiness gives a rough feel to the yarn. Variation in hairiness is a source of weft bars and warp way streaks in the fabric. Long protruding hairs from the yarn contribute to multiple breaks in weaving and fabric faults like stitches and floats.

This problem is solved by applying the compact

spinning systems that increases yarn quality. It is carried out by means

of narrowing and decreasing the width of the band of fibres which come

out from the drawing apparatus before it is twisted into yarn, and by

the elimination of the spinning triangle. It can be used for spinning

both short and long staple yarns.

The compact spinning process produces a new yarn

structure, which approaches the ideal staple fibre yarn construction

even more closely. This has positive effects on raw material use,

productivity, downstream processing, and on the product appearance.

Factors Affecting The Spinning Triangle

The twist

that is transmitted to the yarn in the ring spinning process originates

along the curve between the traveler and front drafting rollers.

Transmission of twists is opposite to the yarn movement in this area.

The traveler transmits twists to already drafted fibres as close as

possible to the clamping point after the front rollers. However, the

twists never reach the clamping point, because after leaving the front

rollers the fibres tend to direct towards yarn axis. The different

lengths of the path of the inner and outer fibres that form the yarn

cause a spinning triangle in ring spinning.

|

If the

spinning triangle is too short (a), then the fibres on the edge must be

strongly deflected to bind them in. This is not possible with all

fibres, and lost as fly. Thus with shorter triangle, smaller weak point

resulting into fewer end breaks but makes the yarn hairy. On the other

hand, a long spinning triangle (b) implies a long weak point and hence

more end breaks giving smoother yarn and less fly.

|

The length of the spinning triangle depends on

spinning geometry and twisting intensity. The form and dimensions of the

spinning triangle significantly influence the structure, surface

characteristics, physical and mechanical characteristics of spun yarn.

Not all fibres that are placed at the external edges of the triangle can

be spun into the yarn structure, and can leave the drafting equipment

without having been spun into the yarn. Such fibres also increase yarn

hairiness.

|

When the Open End (OE) process was commercialised,

the future of conventional ring spinning system was questioned. However, it

is now accepted that ring spinning will continue to remain important because

of its versatility. In view of the long-term prospects of this versatile

spinning system, manufacturers/researchers have further developed and

incorporated innovation on conventional ring spinning system. One of the

examples of such developments is 'Compact Spinning System'. With the

installation of compacting system, the yarn quality is improved, mainly

because of the less hairiness and incorporation of more fibres in the yarn

body.

Compact spinning system

The demand from the modern machines is to run at higher speed, produce

better quality product, which should be suitable for further processing and

give benefit in the downstream processing. Importance also is given to

reduce personnel/labour required, which may not be much relevant in

countries like India where labour is much cheaper. Thus the innovations on

the machines are incorporated keeping these factors in mind.

The demand from the modern machines is to run at higher speed, produce

better quality product, which should be suitable for further processing and

give benefit in the downstream processing. Importance also is given to

reduce personnel/labour required, which may not be much relevant in

countries like India where labour is much cheaper. Thus the innovations on

the machines are incorporated keeping these factors in mind.

Compact spinning is such a system where the yarn can be produced with higher speed, and b etter quality and which gives benefit in the downstream.

Consequently, fabric made from the compact yarn gives better look. In

conventional ring spinning system, the width or spread of the fibres

emerging out from the front roller is greater than width or diameter of the

yarn. Since the twist is not fully penetrated into the front roller nip,

there is always a 'Delta Zone' called "Spinning Triangle" (Figure

1).

etter quality and which gives benefit in the downstream.

Consequently, fabric made from the compact yarn gives better look. In

conventional ring spinning system, the width or spread of the fibres

emerging out from the front roller is greater than width or diameter of the

yarn. Since the twist is not fully penetrated into the front roller nip,

there is always a 'Delta Zone' called "Spinning Triangle" (Figure

1).

If the twists are imparted, the fibres at the edges are either loosely bound or lost as a fly and produce hairy yarn. The main purpose of the Compact Spinning is to eliminate spinning triangle at front roller, technically speaking the 'weakest point' of the ring spinning (Figure 2). The elimination of the spinning triangle results in permanent change of yarn structure, which distinguishes the compact spinning from conventional ring spinning.

Methods of compacting fibre strand

In compact spinning the mass of fibres is condensed before twist is imparted. This condensation happens in so called 'Condensing Zone' following the main drafting zone(1). Different machine manufactures are using different methods to condense the fibres emerging out from the front roller. These methods are:

Compact spinning system

Compact spinning is such a system where the yarn can be produced with higher speed, and b

If the twists are imparted, the fibres at the edges are either loosely bound or lost as a fly and produce hairy yarn. The main purpose of the Compact Spinning is to eliminate spinning triangle at front roller, technically speaking the 'weakest point' of the ring spinning (Figure 2). The elimination of the spinning triangle results in permanent change of yarn structure, which distinguishes the compact spinning from conventional ring spinning.

Methods of compacting fibre strand

In compact spinning the mass of fibres is condensed before twist is imparted. This condensation happens in so called 'Condensing Zone' following the main drafting zone(1). Different machine manufactures are using different methods to condense the fibres emerging out from the front roller. These methods are:

-

Aerodynamically compacting system: a) Suction by drum and b) Suction through perforated apron.

-

Mechanical compact system.

-

Magnetic compacting system.Figure : Conventional (a) and compact (b) ring spun yarns

Aerodynamically compacting system

In this methods the condensation of the fibres strand take place with help of perforated drum or apron. The examples of aerodynamically compacting system are Com4Spin® of Rieter, Elite® Compact Spinning by Suessen, CompACT3 by Zinser, Com4®wool by Cognetex, Olfil system by Marzoli, Toyota's compact spinning, etc. All these methods will be discussed in detail in the subsequent sections.

Com4Spin® of Rieter

Com4Spin® compact spinning system of Rieter produces a yarn what they call COM4® yarn. Com stands for 'comfort 'as claimed by the manufacturer that the wear comfort is increased whereas '4' stands for distinct advantages of yarn(1), namely,

In this methods the condensation of the fibres strand take place with help of perforated drum or apron. The examples of aerodynamically compacting system are Com4Spin® of Rieter, Elite® Compact Spinning by Suessen, CompACT3 by Zinser, Com4®wool by Cognetex, Olfil system by Marzoli, Toyota's compact spinning, etc. All these methods will be discussed in detail in the subsequent sections.

Com4Spin® of Rieter

Com4Spin® compact spinning system of Rieter produces a yarn what they call COM4® yarn. Com stands for 'comfort 'as claimed by the manufacturer that the wear comfort is increased whereas '4' stands for distinct advantages of yarn(1), namely,

-

Lower hairiness

-

Highest strength elongation

-

Unequaled wearing comfort

-

Minimal environmental impact (favourable ecological balance)

The ComforSpin® technology allows aerodynamic parallelization

and condensation of the fibres after the main draft. Com4Spin®

compact process, as comparison to conventional spinning system, is shown in

Figure 3. A 3-over-3 drafting system with double apron is followed

immediately by the fibre compacting zone3. The compact zone consists of

following elements (Figure 4):

-

Perforated drum.

-

Suction system.

-

Bottom roller.

-

Top roller.

-

Nip roller.

-

Air guide element.

The special feature of "Air Guide element" is to enhance the compacting efficiency in the compacting zone (Figure 5). A second top roller located after the compacting zone, the so-called nip roll(5), clamps the spinning triangle. As a result of the compacting process, width 'b' (Figure 3) of the fibre bundle entering the twist insertion zone is considerably smaller than width 'B' of the fibre bundle emerging from the drafting mechanism, so that the size of the spinning triangle is substantially reduced. Subsequent twist insertion is similar to that in the ring spinning process. Optimum interaction of the compacting elements ensures complete compacting of all fibres. This results in the typical properties of yarn as called by Rieter "COM4® yarn".

Figure : Profile of top roller and perforated drum

Characteristics of COM4® yarn

The improvement in the yarn characteristics (Figure 6) due to ComforSpin® Process as claimed by the manufacturer are as follows(4):

Characteristics of COM4® yarn

The improvement in the yarn characteristics (Figure 6) due to ComforSpin® Process as claimed by the manufacturer are as follows(4):

The abrasion resistance (Staff tester) of COM4®

yarn is between 40% to 50% higher.

Hairiness (UT4) is 20-30% lower.

Hairiness (Zweigle S3 values) is much more sensitive

and measured values are up to 60% lower by comparison.

Yarn strength is 8-15% higher.

Capacitive uniformity (UT4) also shows better results

for yarns finer than 40s Ne.

Degree of sizing can be reduced thus reduces the cost

of sizing and subsequent desizing (Figure 7).

Consequently the fabric made from the COM4®

yarn shows higher strength (Figure 8) and more abrasion resistance(5)

(Figure 9).

Suessen Elite® Compact Spinning

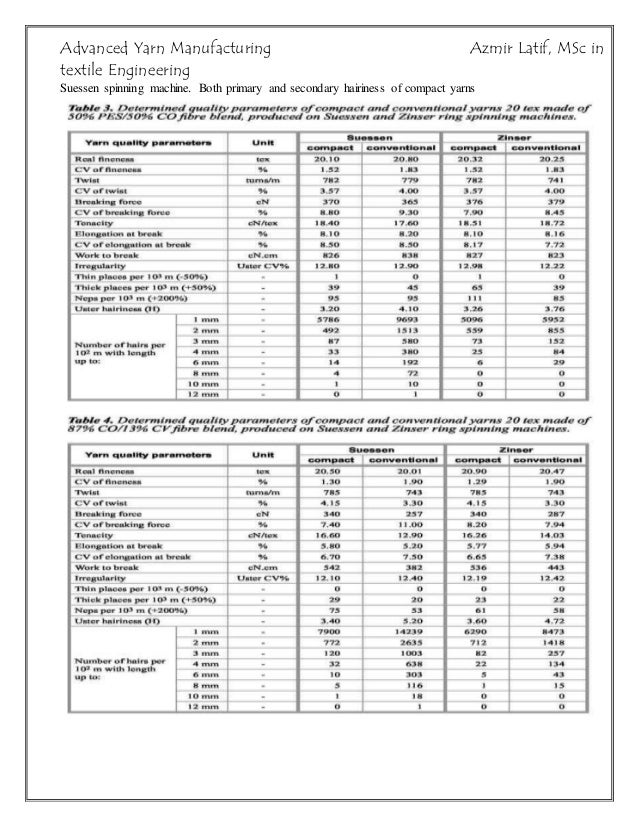

An alternating approach to produce compact yarn is given by Suessen under the name Elite® Compact Spinning(6). As shown in the Figure 10, the drafting system is followed by condensing zone, which consists of profile tube (1), the lattice apron (2) and delivery top roller (3). The delivery top roller (3) is driven by front top roller (5) via a small gear (4). The profile tube (1) is closely embraced by a lattice apron (2) driven by delivery top roller (3). The profile tube is under negative pressure produced by suction unit (6). Profile Tube (1) has an oblique slot (Figure 11) extending up to the clamping point between profile tube and delivery top roller (7).

The fibres emerging from the drafting system are gripped by the airflow created by vacuum and lattice apron and transported towards the oblique edge of the slot and consequently condensed. At the delivery clamping line the fibre strand has achieved optimum condensation. After the clamping line, twist is imparted to an ideally straightened fibre strand, with individual parallel and optimally condensed fibres without protruding hair. In addiction, a slight draft is also applied to enhance consolidation that causes further reduction in the width of the strand during yarn formation.

Two different forms of suction slots are shown in Figure 11. Suction slot of form 'B' is for yarn finer than 30s Ne whereas 'A' type suction slot, with delta shaped beginning, is for yarn coarser than 30s Ne8. For processing carded yarn suction slot of 'A' form should be used whereas for combed and synthetic fibres 'B' type suction slot should be used. Slot applied at a certain angle to the flow of fibres enables the peripheral fibres to be parallelised along yarn core. Suessen offers different Compact Spinning systems for different application(7) as given in Table 1.

An alternating approach to produce compact yarn is given by Suessen under the name Elite® Compact Spinning(6). As shown in the Figure 10, the drafting system is followed by condensing zone, which consists of profile tube (1), the lattice apron (2) and delivery top roller (3). The delivery top roller (3) is driven by front top roller (5) via a small gear (4). The profile tube (1) is closely embraced by a lattice apron (2) driven by delivery top roller (3). The profile tube is under negative pressure produced by suction unit (6). Profile Tube (1) has an oblique slot (Figure 11) extending up to the clamping point between profile tube and delivery top roller (7).

The fibres emerging from the drafting system are gripped by the airflow created by vacuum and lattice apron and transported towards the oblique edge of the slot and consequently condensed. At the delivery clamping line the fibre strand has achieved optimum condensation. After the clamping line, twist is imparted to an ideally straightened fibre strand, with individual parallel and optimally condensed fibres without protruding hair. In addiction, a slight draft is also applied to enhance consolidation that causes further reduction in the width of the strand during yarn formation.

Two different forms of suction slots are shown in Figure 11. Suction slot of form 'B' is for yarn finer than 30s Ne whereas 'A' type suction slot, with delta shaped beginning, is for yarn coarser than 30s Ne8. For processing carded yarn suction slot of 'A' form should be used whereas for combed and synthetic fibres 'B' type suction slot should be used. Slot applied at a certain angle to the flow of fibres enables the peripheral fibres to be parallelised along yarn core. Suessen offers different Compact Spinning systems for different application(7) as given in Table 1.

Table 1: Suessen Compact spinning

systems for different application:

| EliTe®CompactSet-S (for short-staple fibres, cotton, synthetics and blends) |

Yarn Type | EliTe®CompactSet-L (for long-staple fibres wool, synthetics and blends) |

| EliTe®CompactSet-S | Single yarn | EliTe®CompactSet-L |

| EliCore®S | Core Yarn | EliCore®L |

| EliTwist®S | Two-component yarn | EliTwist®L |

| EliCoreTwist®S | Two-component

yarn+ filament core yarn |

EliCoreTwist®L |

Advantages of Elite® Compact Yarn(9)

-

Higher work capacity by 30% (max).

-

Higher yarn strength (Figure 12a) by 20% (max).

-

Better elongation (Figure 12b) by 20%.

-

Lower hairiness (Figure 12c) by 85% (max) Zweigle S3.

-

Better yarn evenness.

-

Lower imperfection value (IPI).

The benefit range of Elite® CompactSet

(red zone) is shown in Figure 13. This range is the product of the two

vectors for quality improvement and production increase(7).

CompACT3 by Zinser

The compact spinning system by Zinser supplied under the trade name of CompACT3, is a pneumatic (aerodynamic) compacting system based on the fibres bundling/compacting via several suction points(10). CompACT3 compacting zone is installed after 3-over-3 double aprons drafting system that consists of perforated aprons which is supplied with low pressure and of drive shaft (Figure 14). The bundle of fibres are guided over a perforation row with circular holes, diameter of which does not suck in the individual fibres and the holes distance, which allows a sufficient fixing over the fibre length (Figure 15).

The dimension of the holes diameter depends on the yarn count. It is claimed by the manufacturer that the compACT3 Apron has been developed in its functional design(10). If it is required to extend the collection area, some of the holes are replaced by ellipses (Figure 16). These are design for including the individual fibres even more at the outside by means of presenting airflow. The distance of the perforation holes is chosen so that the desire hairiness is still kept. It is further claimed that apron design guarantees good fibre transporting feature, optimum sliding characteristics and very long service life under production conditions. The 'willingness to condense' is different for different fibres. This can be tackled with overfeeding of 0% for fibres those are very willing fibres up to an overfeeding of 4% for more critical fibres those are difficult to condense.

CompACT3 by Zinser

The compact spinning system by Zinser supplied under the trade name of CompACT3, is a pneumatic (aerodynamic) compacting system based on the fibres bundling/compacting via several suction points(10). CompACT3 compacting zone is installed after 3-over-3 double aprons drafting system that consists of perforated aprons which is supplied with low pressure and of drive shaft (Figure 14). The bundle of fibres are guided over a perforation row with circular holes, diameter of which does not suck in the individual fibres and the holes distance, which allows a sufficient fixing over the fibre length (Figure 15).

The dimension of the holes diameter depends on the yarn count. It is claimed by the manufacturer that the compACT3 Apron has been developed in its functional design(10). If it is required to extend the collection area, some of the holes are replaced by ellipses (Figure 16). These are design for including the individual fibres even more at the outside by means of presenting airflow. The distance of the perforation holes is chosen so that the desire hairiness is still kept. It is further claimed that apron design guarantees good fibre transporting feature, optimum sliding characteristics and very long service life under production conditions. The 'willingness to condense' is different for different fibres. This can be tackled with overfeeding of 0% for fibres those are very willing fibres up to an overfeeding of 4% for more critical fibres those are difficult to condense.

Figure : Drafting and condensing zone

Advantages of CompACT3 yarn

The advantages claimed by the manufacture are shown in Figure 17. These can be summarised as follows(11):

Advantages of CompACT3 yarn

The advantages claimed by the manufacture are shown in Figure 17. These can be summarised as follows(11):

-

The UT4 hairiness for carded cotton CompACT3 yarn is 20% lower as compared to conventional ring spinning. The S3 hairiness value according to Zweigle reduced by 93% (max).

-

Yarn irregularities (Zellweger Uster) show improvements of 6% (max).

-

25% (max) lower IPI values (Zellweger Uster).

-

20% higher tenacity values compared to the values of conventionally spun yarns.

-

Productivity increase at the spinning machine is 10% (max) through increasing the spinning speed and/or reducing the yarn twist.

-

Displacement of the spinning limit by 15% (max).

Com4®wool by Cognetex

Com4®wool is the trademark of the compact spinning for long staple fibres that Cognetex (an Italian based company) has developed for 'IDEA' make ring spinning machine in cooperation with Rieter(12). This system performs fibre parallelisation and aerodynamic condensation thus reduces the spinning triangle. Compact yarn produced is very tight, smooth and with high strength as all the fibres are taken in by the torsion. Its special structure and uniformity provide considerable advantages compared to conventional yarns. Here front drafting roller is replaced by a perforated drum (Figure 18). This enables the airflow to compact the fibres directly on the drafting cylinder. It is claimed by the manufacturer that for the wool sector, a patented elastic control roller with a slant axis prevents fibres that are being pinched at the same time by the drafting system and the front roller, from being tensioned. The IDEA Com4®wool spinning frame is available in two different configuration of spinning sections:

Com4®wool is the trademark of the compact spinning for long staple fibres that Cognetex (an Italian based company) has developed for 'IDEA' make ring spinning machine in cooperation with Rieter(12). This system performs fibre parallelisation and aerodynamic condensation thus reduces the spinning triangle. Compact yarn produced is very tight, smooth and with high strength as all the fibres are taken in by the torsion. Its special structure and uniformity provide considerable advantages compared to conventional yarns. Here front drafting roller is replaced by a perforated drum (Figure 18). This enables the airflow to compact the fibres directly on the drafting cylinder. It is claimed by the manufacturer that for the wool sector, a patented elastic control roller with a slant axis prevents fibres that are being pinched at the same time by the drafting system and the front roller, from being tensioned. The IDEA Com4®wool spinning frame is available in two different configuration of spinning sections:

-

Compact spinning with conventional spindle.

-

Compact spinning with controlled balloon spindle.

The comparative spinning tests of worsted yarns,

conventional/Com4®wool (100% wool, Nm 40, ?m 104, 10500rpm) 13,

as claimed by the manufacturer, are shown in Figure 19. There is overall

improvement in the yarn quality in comparison to conventional yarn.

Olfil system by Marzoli

Olfil is the compact spinning system designed and developed by Marzoli(14). The condensing system is positioned at the delivery of the drafting unit (Figure 20). The bottom section of the condensing system has one stainless steel pipe for every 8 spindles with a perforated apron at each spindle. The top section of the condensing system is composed of two pressure rollers driven by the toothed belt. For each 48 spindles section, there is one motorised inverter driven fan that provides suction for the condensing system. A wide area air distribution and compensation allows for the correct balancing of the suction.

An exhaust air distribution specially designed to prohibit turbulence that could otherwise damage the spinning provides the possibility for a centralised air recycling system. There is a provision to change the conventional spinning frame to compact spinning frame. It is claimed by the manufacturer that time required for installation of compact system per 8 spindles on Marzoli standard spinning frame is 45 seconds only(14).

Toyota's compacting method

RX240NEW-EST-make Toyota's ring spinning frame is equipped with compact spinning system (Figure 21). The condensing device consists of suction slit and perforated apron and works on aerodynamic compacting principle(15). The special features of the machine, as claimed by the manufacturer are(15):

Olfil system by Marzoli

Olfil is the compact spinning system designed and developed by Marzoli(14). The condensing system is positioned at the delivery of the drafting unit (Figure 20). The bottom section of the condensing system has one stainless steel pipe for every 8 spindles with a perforated apron at each spindle. The top section of the condensing system is composed of two pressure rollers driven by the toothed belt. For each 48 spindles section, there is one motorised inverter driven fan that provides suction for the condensing system. A wide area air distribution and compensation allows for the correct balancing of the suction.

An exhaust air distribution specially designed to prohibit turbulence that could otherwise damage the spinning provides the possibility for a centralised air recycling system. There is a provision to change the conventional spinning frame to compact spinning frame. It is claimed by the manufacturer that time required for installation of compact system per 8 spindles on Marzoli standard spinning frame is 45 seconds only(14).

Toyota's compacting method

RX240NEW-EST-make Toyota's ring spinning frame is equipped with compact spinning system (Figure 21). The condensing device consists of suction slit and perforated apron and works on aerodynamic compacting principle(15). The special features of the machine, as claimed by the manufacturer are(15):

-

Smooth collection of fleece fibres by suction slit and perforated apron.

-

Precise slip-free rotation of the perforated apron because of positive drive of the top and bottom delivery rollers.

-

Inverter-controlled adjustable suction pressure.

-

Easily detachable condensing unit.

-

Perforated apron, driven by a bottom roller, is not affected by top roller diameter.

-

Easy switching over to compact and conventional spinning.

-

Placing the suction ducts on the upper part of the roller stands results in a simplified design and shortened piping route.

-

For easier handling, each 4-spindle condensing unit can be conveniently detached and disassembled without using special tools.

-

The rollers are driven by a geared front-bottom roller and maintenance-free carrier gear, resulting in a simpler structure.

Mechanical Compact System

Mechanical Compacting Spinning (MCS) is given by

Officine Gaudino for long staple. This compact system makes

the compact yarn without the use of air. The compacting of the fibre strand

is carried out with smooth bottom front roller and an angled top roller.

Officine Gaudino offers long staple spinning machine (Model FP 03) with

mechanical compacting system. This compacting system does not require the

additional suction system . The MCS consists of an additional

smooth bottom front roller and an angled top roller. These rollers run at a

slightly slower speed than the front drafting rollers and this 'negative

draft', coupled with offset top roller, creates false twist which compacts

the drafting strand as it comes out from the compacting zone. This system

can be incorporated into the new machines and is claimed to be easily added

or taken off the spinning frame.

Magnetic Compacting System

Magnetic Compact Spinning, as the name implies, is a compacting system that makes the compact yarn with the use of magnetic compactor. The RoCoS compact spinning system, developed by Hans Stahlecker of Rotorcraft Maschinenfabrik, Switzerland is incorporated into LMW's Ring Spinning Frame. RoCoS stands for 'RotorCraft Compact Spinning' system and it works without air suction and uses magnetic mechanical principle only .

Magnetic Compacting System

Magnetic Compact Spinning, as the name implies, is a compacting system that makes the compact yarn with the use of magnetic compactor. The RoCoS compact spinning system, developed by Hans Stahlecker of Rotorcraft Maschinenfabrik, Switzerland is incorporated into LMW's Ring Spinning Frame. RoCoS stands for 'RotorCraft Compact Spinning' system and it works without air suction and uses magnetic mechanical principle only .

Figure : Components of RoCoS device

The bottom rollers(1), support the front roller(2) and delivery roller(3). The condensing zone extends from clamping line A to B. The very precise magnetic compactor(4) is pressed by permanent magnets without clearance against cylinder(1). It forms, together with the bottom roller, an overall enclosed compression chamber whose bottom contour, the generated roller surface of the cylinder, moves synchronously with the strand of fibres and transports this safely through the compactor. The manufacturer offers two types of the compacting system(17):

-

RoCoS 1: Suitable for 100% cotton and cotton/synthetic blends and 100% synthetic fibres with maximum staple length of 60 mm.

-

RoCoS 2: Suitable for 100% wool, 100% synthetic and wool/synthetic blends having minimum staple length of 50 mm.

Thus RoCoS compact spinning system does not require

air suction, air pipes and perforation drum or apron. So it is claimed by

the manufacturer that no extra power, extra maintenance or erection

installation is required for this compacting method.

Precautions for compact spinning system

So these methods can be used to make compact yarn. But to work successfully with compact spinning system certain precautions have to be taken. These precautions are:

Precautions for compact spinning system

So these methods can be used to make compact yarn. But to work successfully with compact spinning system certain precautions have to be taken. These precautions are:

-

Extremely low degree of hairiness results in under lubrication of rings. So it is recommended that rings of higher strength and wear resistance should be used.

-

The overhead cleaner must be equipped with special blower nozzle so that the fibres in compact zone are not disturbed with the blower air.

-

Compact spinning frames must be separated from conventional spinning frames with some partition.

In compact spinning the spinning triangle associated with conventional ring spinning is eliminated by pneumatic compaction, which happens by suction and compaction on a perforated revolving drum/ apron in the front zone of the drafting system. The process is characterised by the introduction of a fourth nip point downstream of the exit from the conventional 3/3 drafting system, which acts as an aerodynamic condenser.

The aerodynamic condensing of the fibres through suction results in narrower spinning zone, and with individual fibres more effectively bound into the yarn assembly, it offers the potential to create a near perfect yarn structure by applying air suction to condense the fibre stream in the main drafting zone, thereby virtually eliminating the spinning triangle.

In conventional spinning a spinning triangle is formed immediately after the drafting mechanism in the ring frame. The spinning triangle is a weak zone due to less twist in this region; under normal working conditions most of the breaks occur near-vicinity of the spinning triangle. The strength of the fibrous mass in the spinning triangle determines the attainable spindle speed. Hence, if the spinning triangle is avoided or its length reduced, the achievable spindle speed would be increased. It is with this objective in mind, compact spinning was being tried.

Compact spinning technology has potential for improving both the quality and profitability aspects of cotton yarn manufacturing. Depending on the objectives of the textile manufacture, different approaches are available. One approach could be to reduce the cost of the raw material, while maintaining quality. Another could be reducing twist, while using the same raw material. Yet another is to eliminate some or all of the combing, while still producing acceptable yarn quality.

Properties of compact yarn compared with that of conventional yarn

With compact spinning yarn, strength and elongation at break are higher. Compact spun yarn has better abrasion resistance. Fabric properties in terms of breaking strength, breaking elongation and tear strength are also better with compact yarn. Table showing the comparison of yarn properties of compact yarn and normal spun yarn are given below.

Abbreviation: ↑Improvement W.R.T.: With Respect To

Results are of bulk production of COMPACT & NORMAL yarn

Benchmarking of compact yarn with conventional ring spun yarn

The following charts benchmark select properties of both combed and carded cotton yarns spun on compact spinning system and conventional ring spinning system. In carded/combed for fine counts, long/extra long cotton is used; same roving is used with respect to each count, on both systems. And highlight the superiority of compact yarn.

Materials and method

These studies were carried out on regular production in different mills by using their regular mixing. On conventional and compact yarn same roving is used and testing is done in their own laboratories.

It can be observed that Compact Combed cotton yarns reported 3 per cent less Irregularity. 30 per cent less IPI, 7 per cent higher RKM, 10 per cent less UT-4 Hairiness and 70 per cent less S3 Hairiness.

Over the conventional combed ring spun yarn.

Similarly compact carded cotton yarn for the same count range resulted in 5 per cent less Irregularity, 35 per cent less IPI, 10 per cent higher RKM, 15 per cent less UT-4 hairiness and 80 per cent less S3 hairiness.

Over the conventional carded ring spun yarn.

Other than yarn hairiness. Other yarn parameters such as strength, elongation, short IPI, Classimat faults, etc of compact yarn are also better than ring spun yarn and these results are advantages in the downstream processing.

Knitting

Due to low hairiness, low pilling tendency ensures good wear behaviour and results in better running properties and improved quality. Since fibre fly and oil cannot combine to form clumps of fly, which are occasionally knitted into the fabric and can cause thread and needle breaks. The wear on guide elements, needles and sinkers is reduced as a result of lower residual dust content of compact yarn. Due to low twist, body twist is also minimised.

Sizing

Clinging tendency of compact yarn displays considerably fewer and less pronounced clinging phenomena. Lower clinging tendency of yarn results in improvement of reparability of the warp. This reduces the cost of sizing and subsequently de-sizing, at the same time, resulting in lesser environment pollution.

Weaving

Despite the lower degree of sizing, thread break rates are lower, which significantly improves efficiency.

Finishing

The higher stretch recovery is also retained in the finished fabric. This is an advantage, especially in shirting fabrics with non-iron finish. Printed fabrics' appearance looks better due to less hairiness.

Twisting

The advantage in spinning also has an impact, when it comes to twisting. In compact yarn, less twist is possible, without any loss of strength. This result in lower manufacturing cost and the opportunity to manufacture new and softer twist yarns.

Singeing

The customary addition of weight to the yarn count, which is burnt off in singeing is no longer necessary. This amounts to raw material saving. The re-winding process, which is usually necessary to remove the singeing dust for the ply/ single yarn can also dispensed with.

Advantages of compact yarn

Other than yarn hairiness, other yarn parameters such as Strength, Elongation, IPI and Uniformity are also better than ring spun yarn and these advantages can also exploited in downstream processing.

Commercialisation

The Compact Spinning System being commercialised is by Rieter is called Com4 Spinning. Suessen system was first introduced to the market at ITMA 99 in Paris. This covers a full spectrum of raw materials and counts.

However, compact spinning system is also made by: Zinser, Toyota, Rotorcraft, etc; which are designed to accommodate the full spectrum of staple length spin today. These compact spinning systems offer the possibility of using cotton with short staple lengths to long, to produce high quality yarns that heretofore required long or extra long staple cottons.

In Compact Spinning there are still doors to open, like carded compact yarn nearly equivalent to conventional combed ring yam, blended yarn, etc; all the possibilities are opening a wide field for the creation and development of future products and applications.

Reduced yarn hairiness and improved tensile properties are the key benefits of the compact yarn. Both characteristics are crucial for yarn performance in downstream manufacturing processes. Compact spinning technology has potential for improving both the quality and profitability.

These can be done by:

• Reducing the cost of raw material while maintaining yarn quality;

• Reducing twist while using the same raw material; and/or

• Eliminating some or all the combing and still producing acceptable yarn quality.

The advantageous compact yarns can be economically utilised in a variety of ways. All these possibilities are opening a wide field for the creation and development of future products and applications, and singeing can be completely or partially dispensed with. It can be said about sizing also, which also is a saving. If the strength of the conventional yarn is sufficient for the intended applications, using the compact technology will allow a reduction of twist. This means, increased production and reduced consumption.

Other benefits are: Printing is more brilliant due to better dye uptake, piling resistance, and increase in lustre and strength. And last but not the least is compact yarn can be spun from less expensive raw materials and conventional combed yarn can be replaced by compact carded yarn.

It has already been proved and established by many researchers and industrial people that the compact yarns have improved quality in comparison to conventional yarns and subsequently results in substantial improvement in the downstream processing. There are many methods offered by the machine manufacturers to choose for making compact yarn. Some of these methods, especially based on aerodynamic compacting, are already proven and running successfully in the mills. Still there is scope for spinning mills to establish the workability of other compacting methods offered by the manufacturers.

Courtesy : ITJ August 2009

ITJ August 2007

No comments:

Post a Comment